10 Benefits of Plant Asset Management Software

Madhurima Sanyal |

12 Jan 2024 |

04:37 AM

- Understanding the Significance of Plant Asset Management Software

- The Evolution of Asset Management Systems in Plant Maintenance

- Asset Management Systems in Plant Maintenance

- Streamlining Plant Maintenance: The Role of Asset Management Systems

- Overview of Asset Management Systems

- The Role of Asset Management Systems in Plant Maintenance

- Preventive Maintenance Planning

- Establishing Robust Preventive Maintenance Strategies

- Work Order Management

- Achieving Precision and Accountability in Maintenance Workflows

- Data Analysis and Reporting

- Asset Performance Monitoring

- Inventory Management

- Plant Asset Management Software - Proptor

- Leveraging Cutting-edge Technology for Plant Maintenance Success

- Conclusion

The Essential Guide to Asset Performance Management for Businesses

Kirti Prakash 10 May 2024 | 16:33 PMTransform the way you manage asset performance with our advanced Asset Performance Management software. Designed to optimize the lifespan and efficiency of your assets, this software empowers businesses to enhance operational reliability and reduce do...

Plant Asset Management Software is more than just a technological innovation; it's a strategic ally in the realm of industrial efficiency. As we learn more about plant asset management, it's essential to comprehend the profound impact this software can have on your operations.

Understanding the Significance of Plant Asset Management Software

At its core, Plant Asset Management Software is a game-changer. It's not merely about managing assets; it's about orchestrating a symphony of efficiency within your plant. Imagine having a tool that not only manage assets but also optimizes their performance, reduces downtime, and enhances overall productivity.

In the complex landscape of industrial operations, the significance of such software becomes apparent. It serves as the linchpin, streamlining tasks, minimizing disruptions, and ensuring the longevity of your critical equipment. It's the digital brain of your plant, constantly analyzing data to provide actionable insights and enable smarter decision-making.

The Evolution of Asset Management Systems in Plant Maintenance

To truly appreciate the prowess of Plant Asset Management Software, let's take a step back and trace the evolution of asset management systems in plant maintenance. From manual record-keeping to the dawn of computerized systems, we've come a long way. Today, with sophisticated software at our disposal, the landscape of plant maintenance has been revolutionized.

We've transitioned from reactive approaches to a proactive stance, thanks to predictive maintenance capabilities. The software doesn't just tell you when a machine is about to fail; it empowers you to address issues before they escalate. This evolution isn't just about technological advancements; it's a paradigm shift in how we perceive and execute plant maintenance.

Asset Management Systems in Plant Maintenance

Exploring the Fundamental Advantages

Plant Asset Management Software acts as the linchpin in optimizing plant maintenance. Picture this: a comprehensive system that not only tracks your assets but also enhances their performance, predicts potential issues, and ensures a seamless flow of operations. It's more than a tool; it's a catalyst for efficiency.

One of the fundamental advantages lies in the proactive nature of these systems. Instead of merely reacting to equipment failures, you're empowered to predict and prevent them. This shift from reactive to preventive maintenance is a game-changer, minimizing downtime and extending the lifespan of critical assets.

But the benefits go beyond maintenance. Asset Management Systems provide a centralized platform for data analysis, offering insights that guide strategic decision-making. From inventory management to performance monitoring, the advantages are multifaceted, creating a domino effect of operational excellence.

Realizing the Potential for Efficiency Gains

Efficiency gains are at the heart of adopting Asset Management Systems. The software doesn't just streamline processes; it orchestrates them for maximum productivity. Consider the impact on maintenance schedules — they become not just plans, but finely tuned strategies aimed at optimizing asset performance.

Through real-time monitoring and predictive analytics, you gain a proactive edge. Imagine identifying a potential equipment issue before it disrupts operations. That's the power of efficiency unleashed by these systems.

In this section, we'll navigate through these advantages, providing you with a roadmap for realizing the potential of Asset Management Systems in revolutionizing your plant maintenance.

Streamlining Plant Maintenance: The Role of Asset Management Systems

Integrating Technology for Seamless Operations

Gone are the days of manual asset tracking system and reactive maintenance. Asset Management Systems usher in a new era by seamlessly integrating technology into every facet of asset maintenance. Imagine a system that not only automates data collection but also analyzes it in real-time, providing actionable insights.

These systems act as digital guardians, continuously monitoring the health of your assets. From predictive analytics predicting potential failures to preventive measures triggered before issues arise, the integration of technology ensures a proactive approach to maintenance. It's not just about fixing what's broken; it's about preventing disruptions altogether.

In this subsection, we'll explore how the infusion of technology into maintenance operations transforms them into efficient, data-driven processes. The result? A plant that operates seamlessly, with minimal downtime and optimal asset performance.

Achieving Operational Excellence through Streamlined Maintenance

The ultimate goal of integrating Asset Management Systems is to achieve operational excellence. Think of it as fine-tuning the engine of your plant, where every component works in harmony. The streamlined maintenance processes enabled by these systems lead to a cascade of benefits.

Downtime becomes a rarity, and the overall lifespan of assets extends significantly. The system not only streamlines the maintenance workflow but also enhances the precision of tasks. Imagine having a maintenance schedule so finely tuned that every action contributes to the overall efficiency of the plant.

As we navigate through this subsection, we'll uncover the tangible benefits of achieving operational excellence, from increased productivity to substantial cost optimization. It's a journey towards a plant that operates at its peak potential, thanks to the streamlined maintenance facilitated by Asset Management Systems.

Overview of Asset Management Systems

Embark on a journey to explore the comprehensive overview of Asset Management Systems and unravel the ten key advantages they bring to enhance plant maintenance efficiency.

10 Advantages of Plant maintenance efficiency

-

Proactive Maintenance Planning: Asset Management System empower you to move from reactive to proactive maintenance. Anticipate issues before they occur, leading to reduced downtime and extended equipment lifespan.

-

Streamlined Work Order Management: Say goodbye to the chaos of operational tasks. These systems streamline work orders, ensuring tasks are organized, prioritized, and executed with precision.

-

In-depth Data Analysis and Reporting: Harness the power of data to make informed decisions. Asset Management System provide comprehensive data analysis and reporting, offering insights that drive strategic maintenance actions.

-

Continuous Asset Performance Monitoring: Monitor the performance of your assets in real-time. Identify patterns, trends, and potential issues, allowing you to optimize asset performance and productivity.

-

Efficient Inventory Management: Eliminate the headache of inventory chaos. These systems facilitate efficient management of spare parts, reducing downtime and ensuring the availability of critical components.

-

Seamless Plant Asset Management Software Integration: Achieve operational synergy by seamlessly integrating Plant Asset Management Software. Ensure that every component of your system works in harmony for optimal efficiency.

-

Enhanced Equipment Reliability: Rely on your equipment with confidence. Asset Management System enhance equipment reliability, minimizing unexpected breakdowns and disruptions.

-

Cost Savings through Preventive Maintenance: Its cost-effectiveness enable strategic preventive measures, leading to significant cost savings over time.

-

Optimized Asset Performance: Unlock the full potential of your assets. Asset Management System optimize asset performance, ensuring that each component contributes to the overall efficiency of your plant.

-

Ensuring Regulatory Compliance: Navigate the complex landscape of regulations with ease. These systems help you ensure compliance with industry standards, reducing the risk of penalties and operational disruptions.

The Role of Asset Management Systems in Plant Maintenance

Understanding the Core Functions

At the heart of every efficient plant maintenance strategy lies the core functions of Asset Management Systems. Picture it as the orchestrator, seamlessly conducting various tasks to ensure the health and longevity of your assets.

Proactive Maintenance Planning: Asset Management Systems shift the paradigm from reactive to proactive maintenance. By analyzing historical data and predicting potential issues, these systems empower you to plan maintenance activities strategically, reducing downtime.

Streamlined Work Order Management: Chaos in operational tasks becomes a thing of the past. These systems organize and prioritize work orders, ensuring tasks are executed with precision and efficiency.

Comprehensive Data Analysis and Reporting: Unlock the power of data for informed decision-making. Asset Management Systems provide in-depth data analysis and reporting, offering actionable insights to guide your maintenance strategies.

Leveraging Technology for Optimal Maintenance Performance

Now, let's into understand the technological prowess that enhances maintenance performance to unprecedented levels.

Real-time Asset Performance Monitoring: Imagine having a digital eye on every asset, monitoring its performance in real-time. Asset Management Systems provide continuous monitoring, enabling you to identify trends, patterns, and potential issues before they impact operations.

Strategic Inventory Management: Say goodbye to inventory headaches. These systems facilitate efficient management of spare parts, reducing downtime and ensuring the availability of critical components.

Seamless Software Integration: Integration is the key to operational harmony. Asset Management Systems seamlessly integrate with plant management software, ensuring every component works together for optimal efficiency.

Preventive Maintenance Planning

Navigating the Landscape of Proactive Maintenance

Ever wished you could predict when a machine might hiccup before it does? That's the essence of proactive maintenance, a paradigm shift from reacting to issues to foreseeing and preventing them. Let's embark on a journey through the landscape of proactive maintenance.

Predictive Analytics Unleashed: Imagine having a crystal ball for your machinery. Preventive Maintenance Planning leverages predictive analytics, scrutinizing historical data to identify patterns that hint at potential failures. This proactive approach minimizes downtime, saving both time and resources.

Condition Monitoring at Its Finest: No more surprises. Proactive maintenance involves constant monitoring of equipment conditions. By keeping a vigilant eye on performance metrics, you can catch anomalies early on, preventing minor issues from snowballing into major breakdowns.

Establishing Robust Preventive Maintenance Strategies

Now that we've navigated the proactive landscape, it's time to chart a course for robust asset management processes. Buckle up for a journey into the realm of structured maintenance planning.

Strategic Work Order Management: Say goodbye to chaotic maintenance schedules. It brings order to the maintenance chaos, streamlining work orders to ensure tasks are executed systematically.

Optimizing Maintenance Schedules: No more arbitrary schedules. With preventive maintenance, schedules are optimized based on equipment performance data, ensuring maintenance activities are conducted when needed, not just when the calendar says so.

Cost-Effective Asset Management: It is not just about preventing breakdowns; it's about managing assets wisely. By addressing issues proactively, you avoid costly emergency repairs and extend the lifespan of your equipment.

Work Order Management

Streamlining Maintenance Tasks through Effective Work Order Systems

Ever felt overwhelmed by the myriad maintenance tasks demanding attention? Enter the hero of streamlined operations—effective work order systems. These systems act as the architects of organized maintenance, ensuring that every task is planned, prioritized, and executed seamlessly.

Prioritization at its Best: With work order management, maintenance tasks are no longer a chaotic jumble. Systems intelligently prioritize tasks based on criticality and urgency, ensuring that your maintenance teams focuses on what truly matters.

Real-Time Visibility: Imagine having a bird's eye view of ongoing maintenance tasks. Work order systems provide real-time visibility, allowing you to track physical assets progress, identify bottlenecks, and make informed decisions on the fly.

Achieving Precision and Accountability in Maintenance Workflows

Precision and accountability are the twin pillars that support effective maintenance workflows. Let's explore how work order management systems bring these crucial elements to the forefront.

Precision Planning: Successful maintenance is all about precision planning. Work order systems enable you to plan maintenance activities with surgical precision, ensuring that resources are allocated efficiently and downtime is minimized.

Accountability Redefined: No more guessing games about who did what. Work order management instills a sense of accountability by assigning tasks, asset tracking completion, and providing a transparent record of every maintenance activity.

Data Analysis and Reporting

Harnessing Data for Informed Decision-Making

Ever wondered how to transform raw data into actionable insights that drive decision-making? Plant asset management software excels in this arena, harnessing the power of data to guide your decision-making process.

Data analysis provides insights into equipment health, performance trends, and potential issues. By tapping into this wealth of information, you can make informed decisions that prevent downtime, enhance efficiency, and optimize resource allocation.

Reporting Insights: A Key Component of Plant Maintenance Excellence

Reporting isn't just about presenting data; it's about telling a story of your plant's health and performance. Here's why reporting is a pivotal component of achieving maintenance excellence.

Clear Visibility: Reporting offers a clear and concise snapshot of your plant's performance metrics. Understand at a glance what's working well and what needs attention, enabling you to take swift and targeted actions.

Performance Benchmarking: Compare current performance against historical data, manufacturing industry standards, or preset benchmarks. This empowers you to identify areas for improvement and set ambitious yet achievable goals for your plant.

Asset Performance Monitoring

Maximizing Operational Output through Continuous Asset Performance Monitoring

Real-Time Insights: Asset Performance Monitoring provides real-time insights into the health and efficiency of your plant assets. Detect anomalies, anticipate potential issues, and ensure your operations are always at their peak.

Proactive Decision-Making: Armed with real-time data, you can make proactive decisions to optimize asset performance. Predictive maintenance becomes a reality, minimizing downtime and maximizing operational output.

The Link between Asset Performance and Overall Plant Productivity

There exists a profound connection between the performance of individual assets and the productivity of the entire plant. Let's unravel this crucial link:

Efficiency Ripple Effect: When each asset operates at its best, the collective efficiency of the plant skyrockets. Asset Performance Monitoring ensures that every gear in the machinery contributes to the overall smooth functioning of the plant.

Cost-Effective Maintenance: By understanding how each asset contributes to the whole, you can prioritize maintenance efforts where they matter most. This not only optimizes costs but also ensures that resources are allocated where they deliver the most significant impact.

Inventory Management

Efficiently Managing Plant Inventories with Advanced Software Solutions

Gone are the days of manual inventory tracking and spreadsheet chaos. Plant Asset Management Software provides a sophisticated solution to streamline inventory management. With advanced software, you gain a comprehensive view of your plant inventories, facilitating better decision-making and resource allocation.

Manual asset tracking software errors can lead to operational hiccups. Asset Management Software automates inventory tracking, reducing errors, and ensuring that stock levels are always accurate. This translates to smoother operations and reduced downtime.

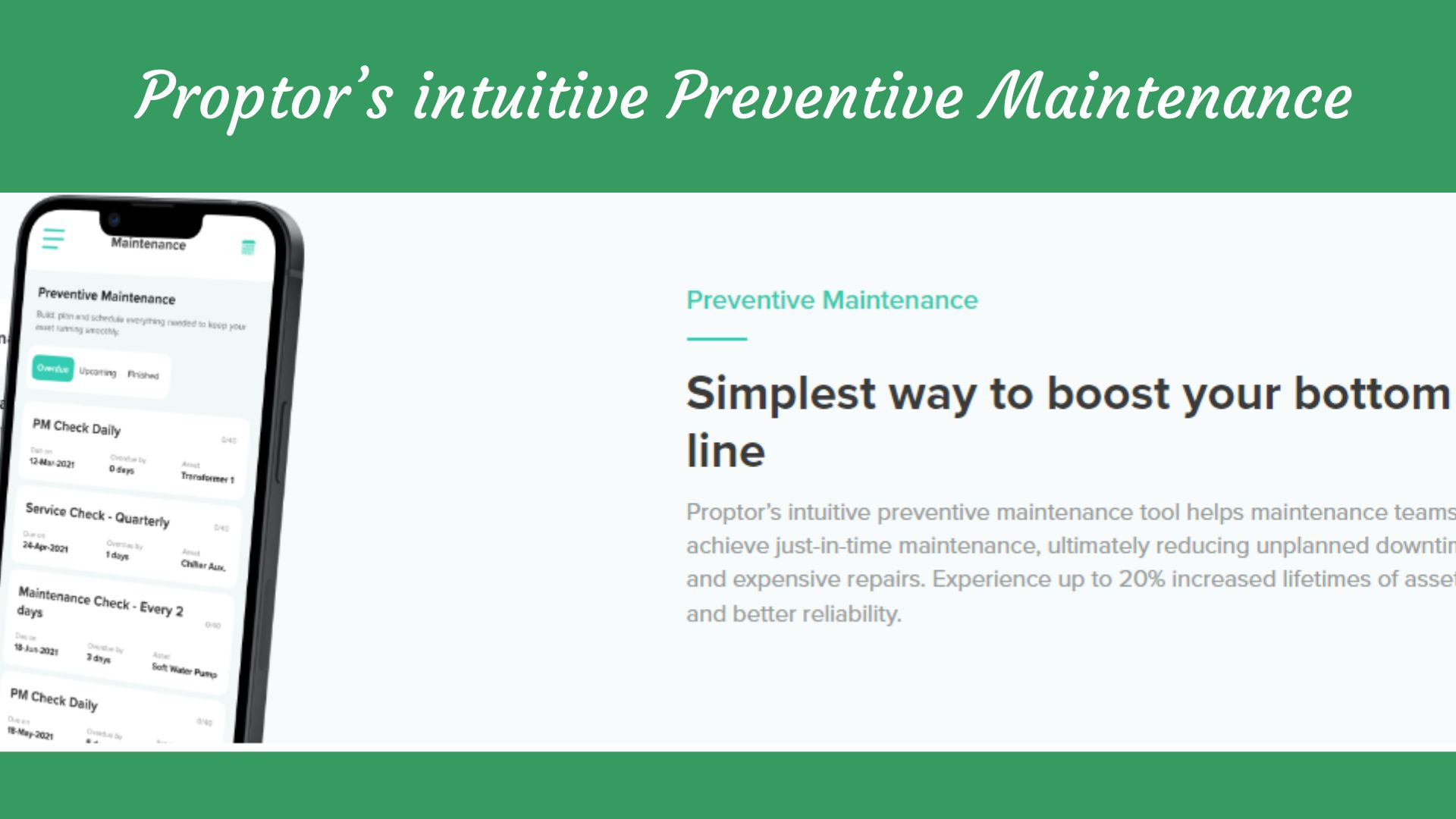

Plant Asset Management Software - Proptor

When it comes to elevating plant asset management, Proptor stands as a game-changer. Proptor redefines the landscape of plant asset management by offering a comprehensive suite of features designed to enhance operational efficiency and reliability.

Real-time Asset Tracking: Gain unparalleled visibility into your plant assets. Proptor facilitates real-time asset tracking, ensuring you know the status and location of each critical component, fostering quicker decision-making.

Predictive Maintenance: Say goodbye to reactive approaches. Proptor utilizes advanced algorithms to predict potential failures, allowing you to address issues before they disrupt operations. This predictive maintenance strategy minimizes downtime and extends the lifespan of your assets.

Leveraging Cutting-edge Technology for Plant Maintenance Success

Proptor doesn't just keep up with technology; it leads the way:

Internet of Things (IoT) Integration: Seamlessly connect and monitor your assets through IoT. Proptor harnesses the power of IoT to provide a connected ecosystem, enabling efficient communication and data exchange between devices.

Augmented Reality (AR) Assistance: Troubleshooting and maintenance become more accessible with AR. Proptor incorporates AR features, offering on-the-spot guidance to maintenance personnel, reducing errors and enhancing overall productivity.

In essence, Proptor transforms the complexities of Asset Management System into opportunities for operational efficiency. Its real-time insights and predictive capabilities pave the way for a new era of maintenance excellence.

Enhanced Equipment Reliability

When it comes to achieving unparalleled equipment reliability, Plant Asset Management Software emerges as the unsung hero. Plant Asset Management Software makes this a reality through:

Proactive Maintenance Strategies: Bid farewell to reactive maintenance. This software employs proactive strategies, scheduling maintenance tasks based on actual equipment conditions. By addressing potential issues beforehand, it prevents unexpected breakdowns, ensuring your equipment operates smoothly.

Data-Driven Insights: Harness the power of valuable data for informed decision-making. Plant Asset Management Software collects and analyzes data from equipment, providing insights into their health and performance. This data-driven approach allows you to make informed decisions about maintenance, optimizing reliability.

Streamlined processes lead to prolonged asset life. Plant Asset Management Software optimizes workflows, reducing unnecessary stress on equipment and contributing to their longevity.

Regular Inspection and Maintenance

In the intricate dance of plant maintenance, regular inspection and maintenance emerge as the choreographers, ensuring each move is precise and sustainable. Regular inspections act as vigilant sentinels, identifying potential issues before they snowball into major problems. By addressing these concerns in their infancy, you prevent costly breakdowns and maintain the overall health of your plant.

Plants are complex ecosystems of machinery. Regular inspections contribute to prolonged asset life by ensuring that each part functions optimally. This not only safeguards your investments but also fosters a sustainable and reliable operational environment.

Cost Savings

Witnessing a substantial reduction in operating costs is a cornerstone benefit of Plant Asset Management Software. By streamlining processes, optimizing workflows, and proactively addressing potential issues, businesses experience a tangible decrease in expenses, contributing to enhanced profitability.

Improved Maintenance Planning

Bid farewell to reactive maintenance approaches. Plant Asset Management Software revolutionizes maintenance planning by introducing proactive strategies. Through predictive analytics and real-time monitoring, businesses can schedule maintenance activities more effectively, minimizing downtime and maximizing asset lifespan.

Optimized Asset Performance

The heart of Plant Asset Management Software lies in its ability to optimize asset performance. By harnessing data-driven insights, businesses can ensure that each asset operates at peak efficiency. This not only extends the lifespan of assets but also boosts overall plant productivity.

Compliance and Regulations

Plant Asset Management Software acts as a vigilant guardian, ensuring that businesses adhere to a myriad of regulatory requirements. By automating asset tracking processes and providing real-time compliance status, the software empowers organizations to stay ahead of audits and regulatory changes, reducing the risk of penalties and operational disruptions.

Conclusion

In the relentless pursuit of operational excellence, businesses stand at the intersection of tradition and technological innovation. The journey through the myriad complexities of industrial landscapes necessitates not just survival but mastery. Plant Asset Management Software emerges as the transformative force, the unsung hero, and the strategic cornerstone that propels industries into a future marked by resilience, efficiency, and sustainable growth.

Planting the Seeds of Transformation

As we traverse the landscape of plant asset management, the roots of transformation are firmly anchored in the soil of technological advancement. Plant Asset Management Software is not merely a tool; it is the catalyst that germinates the seeds of change. By digitizing, automating, and orchestrating intricate processes, the asset tracking system lays the groundwork for a paradigm shift in how industries operate and thrive.

Data and Decision-Making

At the heart of this transformation is the symphony of data and decision-making. Asset Management System conducts this orchestra, harmonizing the diverse and voluminous data generated by industrial assets. Through advanced analytics, real-time monitoring, and predictive insights, businesses gain not just information but actionable intelligence. This, in turn, empowers decision-makers to conduct their symphony with precision, informed by the nuances of asset health, performance, and strategic imperatives.

Efficiency and Cost Savings

Efficiency and optimized cost emerge as twin pillars of success, and Plant Asset Management Software is the crucible in which they are forged. Through streamlined processes, proactive maintenance, and optimized asset performance, businesses unearth the hidden gems of efficiency. The software's ability to anticipate issues before they escalate minimizes downtime, maximizes productivity, and ultimately results in significant cost savings. In an era where every penny counts, this aspect of the asset tracking software becomes the anchor in financial prudence.

Enhanced Equipment Reliability

In the tapestry of industrial success, enhanced equipment reliability paints a vibrant portrait. By bolstering equipment reliability through systematic maintenance, the software extends the lifespan of critical assets. It transforms the narrative from reactive firefighting to proactive asset care, ensuring that machinery operates not just efficiently but sustainably, with long-term reliability at its core.

Compliance and Risk Mitigation

In the ever-evolving landscape of regulations and risks, Plant Asset Management Software emerges as the guiding beacon. The software's prowess in navigating compliance requirements, streamlining reporting processes, and proactively mitigating risks positions businesses on solid ground. It transforms the regulatory maze from a daunting challenge into a navigable course, ensuring not just adherence but resilience in the face of an unpredictable regulatory climate.

Insight and Education

Throughout this exploration, the threads of insight and education have woven a tapestry that extends beyond the mere functionalities of Asset Management System. It is a narrative that underscores the importance of informed decision-making, the value of continuous learning, and the indispensable role of technology in shaping the future of industries.

Embracing Tomorrow with Plant Asset Management Software

As industries stand on the threshold of tomorrow, Plant Asset Management Software beckons them forward. It is not just a solution for the present but a compass guiding businesses into a future where resilience is not a choice but a necessity. The software transforms challenges into opportunities, inefficiencies into streamlined processes, and risks into proactive strategies for success.

The journey with Plant Asset Management Software is not a mere transaction; it is a transformative odyssey. It is a narrative of resilience, efficiency, and sustainable growth, where businesses don't just survive but thrive in the ever-evolving symphony of industrial landscapes. As industries embrace the future, Plant Asset Management Software stands as the steadfast companion, the digital ally, and the catalyst for a new era of operational excellence.