Boosting Manufacturing Efficiency: How CMMS Software Drives Productivity

Madhurima Sanyal |

05 May 2024 |

10:17 AM

- Significance of Efficiency in Manufacturing

- Productivity in Manufacturing vs. Efficiency in Manufacturing: Understanding the Difference

- Here are some ways to improve manufacturing efficiency:

- How Proptor software addresses Maintenance Efficiency Killers

- Preventive Maintenance Scheduling

- Corrective Maintenance Order Tracking

- Reporting

- Conclusion

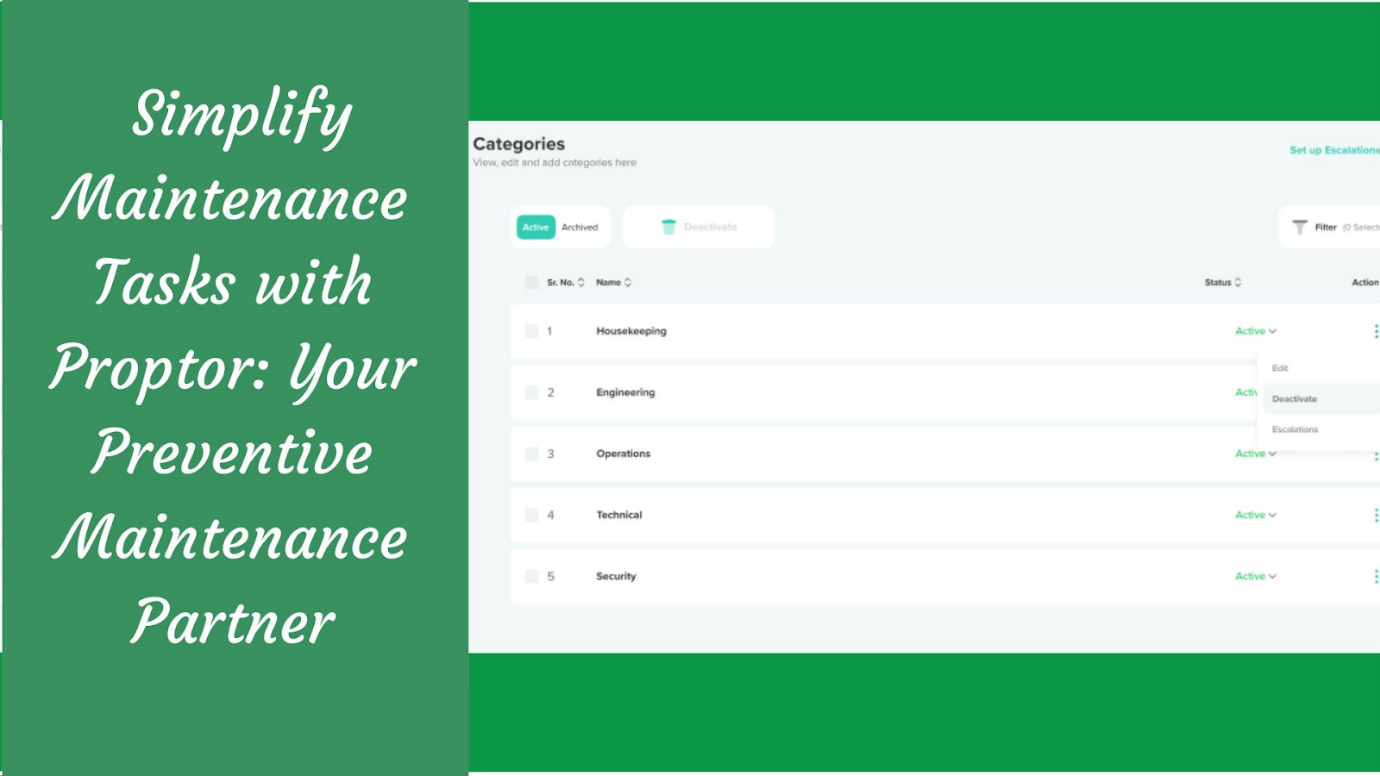

Simplify Maintenance Tasks with Proptor: Your Preventive Maintenance Partner

Shubham Vakharia 05 Jun 2024 | 10:00 AMDiscover how Proptor App streamlines preventive maintenance for property owners and managers, making it easier to schedule tasks, track costs, and ensure timely upkeep for your properties. Get started today! ...

A well-configured CMMS software simplifies maintenance tasks and helps achieve goals faster. Facility managers reap the rewards of CMMS software. This includes increased efficiency, prolonged asset lifespan, minimized downtime, and amplified daily productivity.

Manufacturing focuses on improving production efficiency by reducing costs and increasing throughput. Leveraging lean strategies to drive down production costs while maintaining quality is a constant challenge.

Significance of Efficiency in Manufacturing

Efficiency in manufacturing holds immense significance for both businesses and consumers. It is the cornerstone of productivity and competitiveness in the industry.

Manufacturers save resources and make more products with less by being efficient. This means lower costs and more money for them. Efficiency is also tied to product quality.

It provides higher attention to detail and quality control. Efficiency also keeps workers safe by reducing accidents in well-organized spaces. In today's competitive global market, being efficient is a must for manufacturers. They need it to meet customer needs, save money, and succeed in the long term.

Efficiency in manufacturing is like a dream come true for supervisors. In other words, it's about making a lot of products while using the least amount of time, energy, and money. This helps reduce waste at every step.

Why is efficiency important in Manufacturing?

Well, it's not a saying for the sea; smooth sailing also applies to manufacturing. In this post, we will explore data-backed ideas to boost your business productivity. And transform your operations through CMMS software like Proptor.

Productivity in Manufacturing vs. Efficiency in Manufacturing: Understanding the Difference

Productivity and efficiency might seem similar, but they're not. Let us understand the difference.

-

Productivity is About Output: Productivity measures how much you make against used resources. It's like counting how many cookies you baked with a bag of flour.

-

Efficiency is More Than Numbers: Efficiency looks at the bigger picture. It's not about input and output. It also cares about the quality of work and doing it well.

-

Efficiency is Wider: When you aim for efficiency, you want to do things right, not fast. You use resources well, maintain quality, and reduce risks and losses.

-

Both Are Important: You shouldn't ignore productivity in favour of efficiency. If you can't meet demand, you'll have unhappy customers and miss out on business. Balance between the two is key.

Here are some ways to improve manufacturing efficiency:

-

Reduce Production Waste: Avoid wasting materials and resources during production. You can do it by conducting regular maintenance and implementing quality controls. Providing employee training also helps. Lean manufacturing principles can help cut waste.

-

Identify Bottlenecks: Recognize points in the production process where work gets stuck. It is important to identify what causes delays and inefficiencies. Analyse production capacity, time studies, work-in-process inventory levels, and use the "5 whys" technique to find and address bottlenecks.

-

Improve Employee Attendance: Enhance employee attendance to reduce downtime. This also helps to maintain a consistent production schedule. Consider using absence management software like Proptor to track and manage employee attendance.

-

Automate Operations: Automate manual tasks in the manufacturing process. You can do this by using technology and computer-controlled systems. This reduces human error and speeds up production.

-

Use Manufacturing Software: Put in place manufacturing software to streamline various production processes. This includes production planning, customer relationship management, workforce management, inventory management, and more.

-

Stay Organized: Maintain a clean and organized workplace using the 5S method. This stands for Sort, Set in Order, Shine, Standardize, and Sustain. This method promotes orderliness and efficiency.

-

Prevent Equipment Breakdowns: Focus on preventive maintenance to avoid equipment breakdowns. These causes could be mechanical failure, thermal failure, overload, or contaminated oil. Use predictive data analytics to identify potential issues before they disrupt production.

-

Offer Employee Training: Provide interactive and hands-on training to employees. It will enhance their knowledge and skills. This training should cover the use of technology and equipment. It should also cover company procedures, safety guidelines, and compliance training.

-

Standardize Policies & Best Practices: Create guidelines that document processes, identify successful practices, train employees, track results, and set Key Performance Indicators. These practices will standardize best practices and ensure consistent product quality.

By implementing these strategies, manufacturing plants can improve efficiency and reduce waste. It will finally lead to increased productivity and profitability.

How Proptor software addresses Maintenance Efficiency Killers

Every maintenance manager aims for highest efficiency in their team's work. Yet, unforeseen events can disrupt even the best-laid plans. Scheduling every minute of a maintenance shift is not always a possibility. Unexpected issues can occur any time.

Overloading technicians with a full schedule of preventive maintenance tasks can lead to inevitable breakdowns. This requires corrective maintenance. This disruption is almost guaranteed to cause delays.

This kind of interruption is unavoidable. But there are avoidable maintenance efficiency problems that CMMS software like Proptor can help address.

-

Work Order Templates

Maintenance teams operating without CMMS often use emails and paper documents to manage work orders. This can lead to the inconvenience of maintenance technicians and managers. They must search through their emails to find job instructions that may have been missing.

But CMMS software offers a host of solutions. It allows the creation of preventive maintenance (PM) work order templates. These templates provide accessible instructions for each planned maintenance job. In the process, it eliminates the need to memorize specific job procedures each time.

-

Attachments

Before starting a maintenance job, the team might have to search through paper stacks. This is to locate warranties or owner's manuals, a time-consuming and stressful process. It can lead to delays in carrying out corrective and preventive maintenance work.

CMMS software offers an attachment feature. It enables the upload of necessary supplementary documents for different maintenance jobs.

The maintenance team can view equipment manuals, warranty details, diagrams, troubleshooting guides, and more in the software. These documents are accessible on smartphones or tablets, so there's no need to leave the job site.

-

Maintenance History

Without CMMS, technicians must walk around to ask about work orders or past repairs. CMMS software offers easy access to maintenance history. It helps in saving time and effort in finding needed information.

Quick access to maintenance history helps technicians and managers prepare for their work. CMMS software gathers maintenance information in one place, enabling faster and smarter decision-making.

Less asset downtime is crucial for boosting production output in maintenance management. In maintenance management, reducing asset downtime is essential for maximizing production output.

-

Inventory Management

Maintenance teams without CMMS software struggle with quick access to MRO inventory data. This includes part counts, buy orders, and vendor contacts. They waste time searching the stockroom for parts and not knowing if they are available.

CMMS software simplifies inventory management. It provides employees with real-time information on MRO part's location and sources. This data is always up to date, ensuring accuracy and saving time.

-

Service Requests

Handling maintenance requests can be chaotic without a digital system. Requests come from all directions, and the maintenance team might jump from one job to another. They do this often based on who approaches them first or the urgency of an email.

This reactive approach doesn't meet management or boost productivity. CMMS software streamlines the process by introducing features like maintenance requests. These systems are simple, allowing anyone to submit a request. Maintenance managers can then decide if it should become a work order and set its priority.

A formal maintenance request system also saves technicians time. They can review all requests in one place. Also, check work order statuses, and keep requesters informed. This system helps catch small issues before they become costly repairs.

Preventive Maintenance Scheduling

Creating a preventive maintenance program (PM) can be overwhelming without the right tools. Without scheduled PM for critical equipment, there's a higher chance of downtimes. This can result in a continuous cycle of last-minute corrective work. This can be challenging for the maintenance team to escape.

CMMS systems simplify this by providing easy-to-set-up preventive maintenance schedules. They communicate work requirements and offer advance notice of upcoming preventive maintenance tasks.

With CMMS software, you can streamline maintenance management. You can do this by tracking recurring jobs and their estimated durations. Maintenance managers can schedule preventive maintenance work orders at any needed interval.

Corrective Maintenance Order Tracking

Efficient maintenance in under weather when corrective maintenance work lacks time tracking. This results in unaccounted gaps in time. It's essential to log the timeframes for unexpected corrective maintenance jobs. Especially after their completion to maintain a comprehensive maintenance history.

CMMS software's work order tracking allows you to log the duration of unplanned jobs. This helps to keep a record of labour hours. This helps maintenance managers make better decisions for scheduling and prioritizing work.

Reporting

Without maintenance management software, running reports requires manual effort. This means writing data, entering data in a spreadsheet, and using word processing software. This process is time-consuming and could be better spent on other tasks.

CMMS software provides easy access to electronic records, saving manual effort. For instance, you can access last month's air duct usage costs and compare them to other metrics. All you need to do is access the report, and you'll have data ready to share with management.

Conclusion

CMMS software like Proptor can make a significant difference in manufacturing efficiency. It simplifies maintenance tasks and prolongs asset lifespan. It minimizes downtime and amplifies daily productivity for facility managers.

Efficiency in manufacturing is crucial for businesses and consumers. It saves resources, improves product quality, and keeps workers safe. Manufacturers need efficiency to succeed in the competitive global market.

Productivity and efficiency are different but important. To improve manufacturing efficiency, reduce production waste, identify bottlenecks and improve employee attendance.

Automate operations with technology. Use manufacturing software for better control. Stay organized for efficiency. Prevent equipment breakdowns with regular checks. Offer employee training for skills. Standardize policies for consistency. These steps enhance manufacturing efficiency.

CMMS software helps solve maintenance problems. It provides work order templates and attachments. Maintenance history is easy to access. Inventory management becomes simpler. Service requests are well-organized. Preventive maintenance schedules are efficient. Generate reports without manual work. CMMS boosts manufacturing productivity and efficiency. It's a valuable tool for businesses.

CMMS software like Proptor simplifies maintenance management. It helps track work orders, manage inventory, and handle service requests. It improves productivity and efficiency, helping manufacturers succeed in today's competitive market. Ready to supercharge your maintenance efficiency?

Book a demo now and unlock the future of streamlined maintenance management!