5 Ways Technology Reduces Maintenance Costs

Madhurima Sanyal |

14 Jan 2024 |

16:28 PM

- Defining the Significance of Technology in Reducing Maintenance Costs

- Understanding Equipment Maintenance Costs

- Harnessing Predictive Analytics and Data Visualization

- Top 5 Modern Maintenance Technologies

- Conclusion

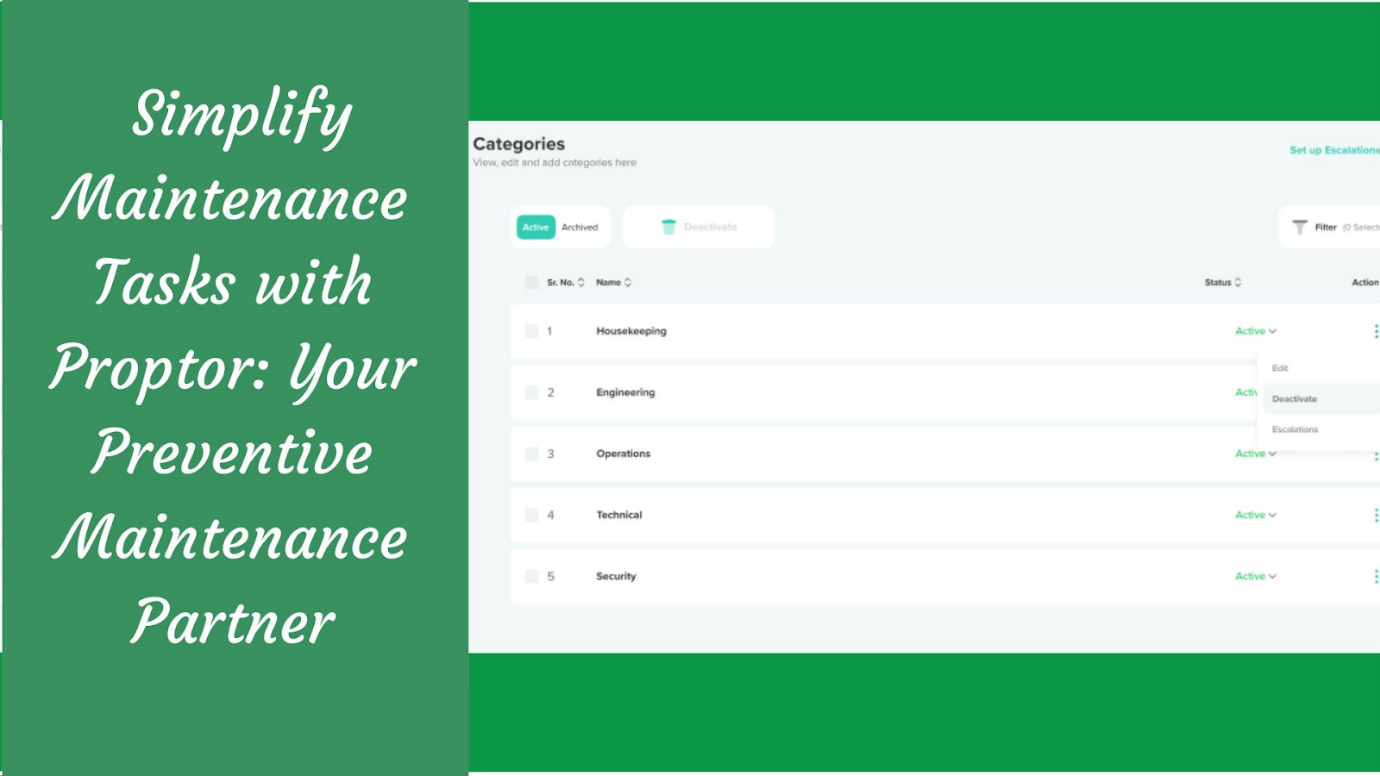

Simplify Maintenance Tasks with Proptor: Your Preventive Maintenance Partner

Shubham Vakharia 05 Jun 2024 | 10:00 AMDiscover how Proptor App streamlines preventive maintenance for property owners and managers, making it easier to schedule tasks, track costs, and ensure timely upkeep for your properties. Get started today! ...

In the dynamic landscape of industry and business, the role of technology in mitigating maintenance costs is nothing short of revolutionary. Whether it's streamlining internal processes for your employees or enhancing the overall experience of your customers, the integration of cutting-edge technology brings forth a profound understanding about the blog subject.

In today's interconnected world, catering to the needs of both customers and employees is essential for sustained success of any business, and technology plays a pivotal role in achieving that delicate balance.

Defining the Significance of Technology in Reducing Maintenance Costs

Let's start by demystifying the profound impact of technology on maintenance cost. Technology, when strategically employed, becomes the cornerstone for productivity, cost-effectiveness, and streamlined operations. Gone are the days of reactive maintenance; technology allows us to transition into a proactive approach, identifying issues before they escalate into costly problems.

In this blog, we will explore five actionable strategies, each representing a beacon of hope for businesses seeking to trim maintenance expenditures without compromising operational integrity. The exploration begins with the recognition of the cost-effective and reliable nature of high-quality replacement parts.

Next, we advocate for the implementation of preventative maintenance scheduling as a proactive measure to prevent breakdowns and prolong new equipment lifespan. The significance of empowering employees with training for timely maintenance issue identification is underscored, emphasizing the reduction of downtime.

We then shift focus to the critical role of regular lubrication and functional grease fittings in enhancing equipment longevity, with a nod to technological advancements in creating efficient lubrication schedules. Finally, the transformative potential of Computerized Maintenance Management System (CMMS) is unveiled, emphasizing the shift from reactive to predictive maintenance approaches.

Understanding Equipment Maintenance Costs

In the world of business and industry, navigating equipment maintenance costs is like traversing a complex financial landscape. By understanding the financial intricacies of maintenance costs and embracing technology-driven decision-making, you pave the way for a cost-effective and sustainable approach to equipment management.

How Equipment Maintenance Costs are Calculated

Calculating maintenance costs involves a nuanced approach, considering not only direct expenses like spare parts and labor but also indirect costs associated with downtime, energy consumption, and potential risks.

Direct costs cover the expenses directly tied to repairs and replacement parts. Simultaneously, indirect costs factor in the financial implications of equipment downtime and potential safety hazards.

Equipment Maintenance vs. Equipment Replacement

Let's compare maintaining existing equipment with opting for replacements. This decision-making process is pivotal in shaping your budget and long-term financial strategy. Technology, through data analytics and predictive maintenance tools, emerges as the guiding force.

Modern technology empowers businesses to make informed decisions. Predictive analytics, for instance, allows you to foresee potential failures, enabling proactive maintenance and minimizing unexpected downtime. This not only extends the lifespan of your equipment but also substantially reduce maintenance costs.

Strategies for Reducing Equipment Maintenance Costs

Reducing equipment maintenance costs is not just a goal; it's a strategic imperative for businesses aiming at optimal efficiency. In this section, we'll dissect practical strategies that leverage technology to curtail expenditures without compromising performance.

Using High-Quality Replacement Parts

Your equipment is only as reliable as the parts that comprise it. Investing in high-quality replacement parts might seem like an upfront cost, but it's a long-term solution that minimizes breakdowns and extends the lifespan of your assets.

Implementing Preventive Maintenance Scheduling

Prevention is the cornerstone for reducing operating costs. By adopting preventive maintenance scheduling, you proactively address potential issues before they escalate. Technology, through advanced scheduling tools, enables you to streamline maintenance tasks, reducing the chances of costly breakdowns.

Employee Training for Maintenance Issue Identification

Your workforce is your first line of defense against regular maintenance challenges. By providing training on identifying and reporting issues promptly, you empower your maintenance team to be proactive problem solvers. This not only minimizes downtime but also contributes to a culture of accountability.

Regular Lubrication and Ensuring Grease Fittings are Functional

Simple yet crucial, regular lubrication ensures the smooth operation of machinery. Technological advancements in predictive analytics help you optimize lubrication schedules, ensuring that your equipment functions at its best, reducing wear and tear.

Utilizing CMMS Software

Enter the era of Computerized Maintenance Management Systems (CMMS). These software solutions revolutionize how you manage maintenance tasks. From tracking work orders to managing spare parts inventory, CMMS streamlines processes, enhancing productivity and reducing costs. In addition to empowering your maintenance teams with real-time information and efficient communication channels, CMMS facilitates seamless collaboration between employees and suppliers.

Sourcing Spare Parts from Reliable Suppliers

The importance of reliable suppliers cannot be overstated. Aligning with trustworthy suppliers ensures timely access to genuine parts, minimizing downtime and avoiding the potential pitfalls of subpar replacements. Moreover, fostering strong collaborations with skilled maintenance teams adds another layer of resilience to your operations.

Incorporating these strategies into your maintenance approach not only reduce maintenance costs but also establishes a foundation for efficient and sustainable operations. Embrace the power of technology, and witness the transformative impact on your bottom line.

Harnessing Predictive Analytics and Data Visualization

In the realm of maintenance cost reduction, predictive analytics and data visualization emerge as formidable allies. Let's delve into the transformative impact of these technologies, offering practical insights into proactive maintenance strategies and enhanced decision-making.

Predictive Analytics: Proactive Maintenance Strategies

Predictive analytics isn't just a buzzword; it's a game-changer in the realm of equipment maintenance. By analyzing historical data, predicting potential issues, and identifying failure patterns, predictive analytics enables businesses to shift from reactive to proactive maintenance strategies.

Predictive Analytics: Proactive Maintenance Strategies

Imagine foreseeing a potential equipment breakdown before it happens. Predictive analytics does just that. By leveraging machine learning algorithms, it identifies subtle signs of deterioration, allowing you to address issues before they escalate. This not only minimizes downtime but also result in significant cost savings associated with emergency repairs.

Data Visualization Tools: Enhancing Decision-Making

Numbers tell a story, and data visualization tools are the storytellers. They transform complex data into easily understandable visual representations, empowering decision-makers with actionable insights.

Data visualization assets, such as charts and graphs, provide a clear snapshot of maintenance trends and performance metrics. Imagine effortlessly identifying patterns, recognizing areas for improvement, and making informed decisions—all at a glance. These tools simplify the decision-making process, ensuring that your strategies are data-driven and result-oriented.

Incorporating predictive analytics and data visualization into your maintenance toolkit isn't just about adopting new technology; it's about revolutionizing how you approach maintenance. By anticipating issues and making informed decisions, you pave the process for significant cost savings and productivity.

Top 5 Modern Maintenance Technologies

-

Mobile CMMS for Workflow Improvement

Mobile Computerized Maintenance Management Systems (CMMS) empower your workforce to manage work orders, track equipment status, and access critical information seamlessly from their mobile devices. This not only improves response times but also ensures a more agile and responsive maintenance workflow.

-

Visual Inspection Tools for Remote Monitoring

Equipped with cameras and sensors, they allow technicians to inspect equipment and troubleshoot issues from afar. It's like having a virtual pair of eyes on the ground that minimizes the need for physical presence and cut costs.

-

Condition-Monitoring Sensors for Predictive Maintenance

Predictive maintenance becomes a reality with condition-monitoring sensors. These sensors continuously collect data on equipment performance, detecting subtle changes that indicate potential issues. By predicting maintenance needs before they become critical, businesses can increase more uptime and avoid costly repairs.

-

Augmented Reality and Virtual Reality for Remote Maintenance

Step into the realm of augmented reality (AR) and virtual reality (VR) for a transformative maintenance experience. Technicians equipped with AR glasses can access real-time data, overlays of equipment information, and step-by-step guidance for repairs. VR, on the other hand, facilitates immersive training experiences, enhancing skills without the need for physical equipment access.

-

Cloud Technology for Data Management and Analytics

The cloud isn't just a buzzword; it's a game-changer for maintenance data management. It centralizes data storage, ensuring seamless access for authorized personnel from anywhere. Moreover, it facilitates advanced analytics, allowing organizations to glean valuable insights, optimize maintenance strategies, and ultimately reduce maintenance cost.

Conclusion

In the pursuit of increasing productivity and cost-effectiveness, the integration of modern maintenance technologies emerges as the key to unlocking a new era in operational excellence. Embracing these advancements doesn't just enhance efficiency; it also allows organizations to automate repetitive tasks. From mobile CMMS ensuring agile workflows to the immersive experiences of augmented reality, businesses stand at the forefront of a transformative journey.

By harnessing the power of predictive analytics, remote monitoring, and cloud-driven insights, maintenance processes become not just responsive but anticipatory. As we bid farewell to traditional paradigms, the future promises not only reduce costs but a landscape where new technologies propel maintenance into a realm of unprecedented efficiency and sustainability.