Reduce downtime with Asset Health Reliability Insights

Viki Dongare |

22 Apr 2024 |

16:06 PM

- Understanding the Importance of Asset Health Reliability Insights

- The Impact of Downtime on Productivity

- Optimizing Asset Performance with Asset Health Insights

- Track and Identify Opportunities for Optimization

- Anticipate and Prevent Asset Failures

- Setting Performance Targets and KPIs

- Implementing Effective Asset Maintenance Strategies

- Overview of Key Maintenance Strategies

- Utilizing CMMS Metrics for Enhanced Asset Health

- Key CMMS Metrics as Indicators of Asset Health

- Taking Asset Management to the Next Level

- Introduction to Asset Management Solutions

- Integrating Asset Health Insights for Improved Management

- Conclusion

Why PPM is essential to maintenance management

Madhurima Sanyal 03 Apr 2024 | 08:32 AMDiscover the power of Planned Preventative Maintenance (PPM) in optimizing asset performance, minimizing downtime, and achieving long-term cost savings. Embrace proactive maintenance strategies to streamline operations and ensure the reliability of yo...

In today's rapidly evolving industrial landscape, businesses are increasingly recognizing the critical role that asset health reliability insights play in maintaining operational excellence. Asset health, encompassing the overall condition and performance of machinery, equipment, and facilities, serves as a cornerstone for sustainable operations. By leveraging advanced analytics and predictive techniques, organizations can gain valuable insights into the health and performance of their assets, enabling proactive maintenance and informed decision-making.

Understanding the Importance of Asset Health Reliability Insights

Asset health insights offer a comprehensive understanding of asset conditions, ranging from performance trends to potential failure indicators. By continuously monitoring asset health metrics, businesses can detect early warning signs of deterioration, preventing costly unplanned downtime and optimizing asset performance. This proactive approach not only minimizes operational disruptions but also enhances overall productivity and efficiency.

The Impact of Downtime on Productivity

Downtime poses a significant challenge to organizations across industries, resulting in lost revenue, decreased productivity, and increased maintenance costs. Whether caused by asset failures, maintenance delays, or unforeseen breakdowns, downtime disrupts operations and compromises business continuity. In today's competitive market landscape, where operational efficiency is paramount, minimizing downtime is essential for maintaining a competitive edge.

The consequences of downtime extend beyond immediate financial losses, impacting customer satisfaction, employee morale, and brand reputation. As businesses strive to meet demanding production schedules and customer expectations, the ability to mitigate downtime becomes increasingly critical. By proactively managing asset health and reliability, organizations can reduce the frequency and duration of downtime events, ensuring uninterrupted operations and maximizing productivity.

In the following sections, we will learn about the strategies and technologies that enable businesses to harness the power of asset health reliability insights. From preventive maintenance schedules to advanced analytics, we will explore actionable steps to optimize asset performance, minimize downtime, and drive operational excellence.

Optimizing Asset Performance with Asset Health Insights

Leveraging asset health insights is key to achieving this objective, as it enables organizations to track and identify opportunities for optimization, anticipate and prevent asset failures, and set performance targets and key performance indicators (KPIs).

Track and Identify Opportunities for Optimization

Asset health insights provide organizations with real-time visibility into the condition and performance of their assets. By tracking key metrics such as equipment uptime, failure rates, and maintenance costs, businesses can identify areas where performance can be optimized. For example, analyzing historical data may reveal patterns of asset underutilization or recurring maintenance issues, prompting proactive measures to address inefficiencies.

Anticipate and Prevent Asset Failures

One of the most significant benefits of asset health insights is the ability to anticipate and prevent asset failures before they occur. By monitoring asset health indicators such as vibration, temperature, and fluid levels, organizations can detect early warning signs of potential failures and take preventive action. Implementing predictive maintenance schedules based on asset health data helps reduce the likelihood of unexpected breakdowns, minimize downtime, and extend the lifespan of critical assets.

Setting Performance Targets and KPIs

Effective asset management requires clear performance targets and KPIs to measure progress and drive continuous improvement. Asset health insights enable organizations to establish meaningful benchmarks for asset performance, reliability, and maintenance costs. By aligning performance targets with business objectives, such as maximizing asset uptime and minimizing maintenance costs, organizations can prioritize resources and investments to achieve optimal outcomes.

Implementing Effective Asset Maintenance Strategies

Overview of Key Maintenance Strategies

Preventive Maintenance - Preventive maintenance involves scheduled inspections, routine servicing, and proactive repairs to prevent asset failures before they occur. By adhering to a predetermined maintenance schedule based on asset health insights and historical data, organizations can minimize the risk of unplanned downtime and extend the lifespan of assets.

Predictive Maintenance - Predictive maintenance utilizes advanced analytics and predictive modeling techniques to forecast asset failures and prioritize maintenance activities. By analyzing real-time asset health data, such as vibration patterns, temperature fluctuations, and equipment usage, organizations can identify potential issues early and take corrective action to prevent costly breakdowns.

Corrective Maintenance - Corrective maintenance involves addressing asset failures reactively, usually in response to equipment breakdowns or malfunctions. While corrective maintenance is unavoidable, organizations can minimize its impact by implementing rapid response protocols, maintaining an inventory of critical spare parts, and optimizing repair processes.

Condition-Based Maintenance - Condition-based maintenance relies on continuous monitoring of asset conditions to determine the optimal timing for maintenance interventions. By leveraging sensor data, IoT devices, and predictive analytics, organizations can detect abnormalities in asset performance and proactively schedule maintenance activities when necessary.

Reliability-Centered Maintenance - Reliability-centered maintenance focuses on identifying the most critical assets within an organization and developing tailored maintenance strategies based on their specific reliability requirements. By prioritizing resources and investments on high-value assets, organizations can maximize uptime and minimize maintenance costs.

Total Productive Maintenance -Total productive maintenance aims to optimize the overall effectiveness of production systems by involving all stakeholders in the maintenance process. By fostering a culture of proactive maintenance and continuous improvement, organizations can enhance asset reliability, operational efficiency, and employee engagement.

Leveraging Maintenance Management Software-To streamline and automate maintenance processes, organizations can leverage maintenance management software (CMMS). These software solutions facilitate asset tracking, work order management, inventory control, and performance analysis, enabling organizations to optimize maintenance activities and improve asset health.

By implementing a comprehensive asset maintenance strategy and leveraging advanced maintenance management software, organizations can enhance operational efficiency, reduce downtime, and drive sustainable business growth.

Utilizing CMMS Metrics for Enhanced Asset Health

In the modern industrial landscape, where operational efficiency is paramount, organizations rely heavily on Computerized Maintenance Management Systems (CMMS) to optimize asset health and streamline maintenance processes. By harnessing key CMMS metrics as indicators of asset health, businesses can gain invaluable insights into the condition, performance, and reliability of their assets, empowering them to make proactive maintenance decisions and drive continuous improvement.

Key CMMS Metrics as Indicators of Asset Health

1. Asset Health Score: The asset health score is a comprehensive metric that provides a holistic assessment of an asset's overall condition and performance. By aggregating data from various sources, including maintenance logs, sensor readings, and historical records, organizations can calculate an asset health score that reflects its current health status. This metric serves as a valuable benchmark for monitoring asset health trends over time and prioritizing maintenance activities. A higher asset health score indicates better overall asset condition and reliability.

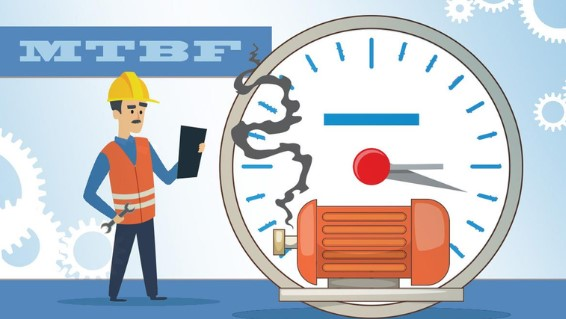

2. Mean Time Between Failures (MTBF): MTBF is a critical metric that measures the average time elapsed between asset failures. By analyzing MTBF data, organizations can identify assets with high failure rates and proactively address underlying issues to improve reliability and minimize downtime. MTBF calculations also inform preventive maintenance schedules, allowing organizations to optimize maintenance activities and reduce overall maintenance costs. A higher MTBF signifies better asset reliability and longer periods of uninterrupted operation.

3. Mean Time to Repair (MTTR): MTTR measures the average time required to repair a failed asset and restore it to operational status. By tracking MTTR data, organizations can evaluate the efficiency of their maintenance processes and identify opportunities for improvement. Minimizing MTTR is essential for reducing downtime and maximizing asset uptime, ultimately improving operational efficiency and productivity. A lower MTTR indicates faster response and resolution times, leading to reduced disruptions and enhanced asset performance.

4. Understanding Asset Statuses and Changes - CMMS systems provide organizations with real-time visibility into asset statuses and changes, enabling maintenance teams to monitor asset conditions and track maintenance activities efficiently. By capturing data on asset performance, maintenance history, and work order status, CMMS systems enable organizations to identify trends, detect anomalies, and make data-driven decisions to optimize asset health.

Moreover, understanding asset statuses and changes allows maintenance teams to effectively plan and execute maintenance activities, minimizing disruptions and maximizing asset uptime. By leveraging CMMS-generated reports and dashboards, organizations can gain comprehensive visibility into asset health metrics, track key performance indicators, and identify areas for improvement.

The utilization of CMMS metrics for enhanced asset health is essential for organizations seeking to improve operational efficiency, minimize downtime, and maximize asset performance. By analyzing key metrics such as asset health score, MTBF, and MTTR, organizations can proactively manage asset health, reduce maintenance costs, and drive business success. Additionally, understanding asset statuses and changes enables maintenance teams to effectively monitor asset conditions and respond promptly to maintenance needs, ensuring optimal asset performance across the entire enterprise.

Taking Asset Management to the Next Level

Asset management is a critical aspect of ensuring the smooth operation and longevity of business assets. It involves the systematic planning, tracking, and maintenance of assets to optimize performance, reduce costs, and minimize downtime. In today's digital age, organizations have access to a wide range of asset management solutions that leverage advanced technologies and analytics to streamline operations and enhance asset health.

Introduction to Asset Management Solutions

Asset management solutions encompass a variety of tools and platforms designed to address the unique needs of different industries and organizations. These solutions often include features such as asset tracking, maintenance scheduling, work order management, and performance analytics. By centralizing asset information and automating key processes, asset management solutions enable organizations to gain better visibility into their asset portfolios and make data-driven decisions to improve efficiency and productivity.

Integrating Asset Health Insights for Improved Management

One of the most significant advancements in asset management is the integration of asset health insights. By leveraging advanced analytics and real-time monitoring technologies, organizations can gain valuable insights into the health, performance, and reliability of their assets. These insights allow organizations to proactively identify potential issues, prioritize maintenance activities, and optimize asset performance.

Integrating asset health insights into asset management solutions enables organizations to make informed decisions about maintenance priorities, resource allocation, and asset investments. For example, predictive analytics can help organizations anticipate asset failures before they occur, allowing them to take preventive action and avoid costly downtime. Similarly, real-time monitoring technologies can provide organizations with up-to-date information about asset conditions, enabling them to make timely interventions and optimize asset performance.

Furthermore, integrating asset health insights into asset management solutions allows organizations to track key performance metrics and KPIs. By monitoring metrics such as asset uptime, maintenance costs, and energy consumption, organizations can identify areas for improvement and implement targeted strategies to enhance operational efficiency. For example, organizations can use historical data to identify trends and patterns, allowing them to develop predictive maintenance schedules and optimize resource utilization.

Asset management solutions play a crucial role in helping organizations optimize asset performance, reduce costs, and minimize downtime. By integrating asset health insights into asset management practices, organizations can take their asset management to the next level, gaining better visibility into asset health and making data-driven decisions to improve efficiency and productivity. With the right combination of technology, analytics, and strategy, organizations can unlock new opportunities for growth and success across the entire enterprise.

Conclusion

In today's competitive business landscape, where operational efficiency and asset reliability are paramount, effective asset management is essential for organizations striving to achieve sustainable growth and success. Throughout this exploration of asset health, operational efficiency, and the integration of advanced analytics, it's evident that leveraging asset management solutions and insights can significantly enhance organizational performance and resilience.

By adopting asset management solutions, organizations can streamline operations, optimize resource allocation, and improve decision-making processes. These solutions provide a centralized platform for managing assets, facilitating seamless communication between maintenance teams, and enabling real-time monitoring of asset conditions. Moreover, asset management solutions empower organizations to proactively identify maintenance needs, prioritize tasks, and implement preventive measures to mitigate risks and minimize downtime.

The integration of asset health insights further elevates asset management practices by providing organizations with valuable data-driven insights into asset performance, reliability, and health. Through prescriptive analytics and predictive technologies, organizations can anticipate potential asset failure, optimize maintenance schedules, and maximize asset uptime. By harnessing the power of asset health insights, organizations can increase cost savings, improve asset reliability, and enhance overall operational efficiency.

Furthermore, asset management solutions enable organizations to track key performance metrics and KPIs, providing valuable insights into asset utilization, maintenance costs, and energy consumption. By monitoring these metrics, organizations can identify areas for improvement, implement targeted strategies, and measure the impact of their asset management initiatives. This data-driven approach empowers organizations to continuously optimize asset performance, reduce costs, and drive business growth.

Taking asset management to the next level requires a strategic and holistic approach that incorporates both advanced technology like artificial intelligence and effective management practices. By embracing asset management solutions and integrating asset health insights, organizations can unlock new opportunities for efficiency, productivity, and innovation. As technology continues to evolve and organizations face new challenges, it's essential to stay agile, adaptive, and proactive in managing assets and driving organizational success.

Ultimately, by prioritizing asset health, operational efficiency, and data-driven decision-making, organizations can build a resilient foundation for long-term growth and competitiveness in today's dynamic business environment. Through continuous improvement, collaboration, and innovation, organizations can unlock the full potential of their assets and achieve sustainable success across the entire enterprise.