Simplify Maintenance Tasks with Proptor: Your Preventive Maintenance Partner

Shubham Vakharia |

05 Jun 2024 |

10:00 AM

- What is Preventive Maintenance

- There are two types of activities in preventive maintenance:

- Objectives of Preventive Maintenance Optimization

- 10 Preventive Maintenance Management Planning Tips

- Here are some tips to enhance preventive maintenance planning:

- Measuring Effectiveness of Preventive Maintenance Activities

- Answering these questions will help improve your preventive maintenance processes.

- Preventive Maintenance Problems and Solutions

- Partner with Proptor App to optimize efficiency

- Conclusion

5+ Best Enterprise Asset Management Software

Kirti Prakash 20 Jun 2024 | 16:12 PMDiscover the 5+ best enterprise asset management software solutions for 2024. Compare features, benefits, and find the perfect EAM software for your business needs....

Equipment breakdowns disrupt business operations and affect profits. Effective planning and scheduling enhance maintenance teams. Equipment efficiency impacts an organization's success. Preventive maintenance improves asset health and reliability.

Preventive maintenance ensures equipment functions as intended. Insanity is doing preventive maintenance on faulty equipment. This article covers preventive maintenance objectives, evaluation, and optimization.

It shields against unexpected breakdowns. Unlike reactive maintenance, it prevents issues. PMO enhances preventive maintenance with data analysis. It customizes maintenance plans for specific equipment and context.

What is Preventive Maintenance

Preventive maintenance acts as a proactive barrier against unexpected equipment breakdowns and malfunctions. Unlike reactive maintenance, preventive maintenance aims at averting these problems from the outset. It includes scheduled inspections, routine upkeep, and component replacements. All these factors are work towards forestalling failures and breakdowns before they manifest. This only saves time but also mitigates the detrimental effects of unforeseen downtime. This can disrupt production and revenue.

Preventive Maintenance Optimization (PMO) takes preventive maintenance to a more advanced stage. It extends beyond the simple execution of routine tasks. Instead focuses on executing them with the highest level of efficiency. PMO means looking at data and analyzing risks. Basis observations, make special plans for equipment and how things work.

PMO doesn't follow general schedules. It considers the special qualities of each piece of equipment. This encompasses usage patterns, environmental conditions, historical failure records, and manufacturer recommendations. By doing so, organizations can maximize the advantages of preventive maintenance. This minimizes unnecessary interruptions and expenses.

Preventive Maintenance Optimization (PMO) is all about making regular maintenance better. It means using data, thinking about risks, and creating specific plans to do maintenance, when it's necessary. This reduces downtime and makes equipment last longer. This raises efficiency and cost-effectiveness

There are two types of activities in preventive maintenance:

Operator Checks and Maintenance PMs.

1. Operator Checks:

-

Operators can perform equipment checks.

-

Engage operators in the process.

-

Operators handle simpler checks, like belt deflection or temperature.

-

This saves maintenance labour hours.

2. Maintenance PMs:

-

Maintenance technicians, or PMs, perform planned tasks.

-

Regular inspections, such as checking pumps or chain drives.

-

The goal is to keep equipment running as intended.

Objectives of Preventive Maintenance Optimization

Preventive Maintenance Optimization has specific goals that go beyond regular preventive maintenance:

-

Efficiency Improvement: Optimization focuses on getting rid of unnecessary maintenance tasks. These tasks hinder equipment reliability. It helps organizations use their resources better.

-

Downtime Reduction: By using data and predictions, optimization helps prevent unexpected downtime. It does this by fixing issues before they cause equipment breakdowns.

-

Customization for Variability: Optimization makes maintenance plans that suit each piece of equipment. This ensures they get the right care without overdoing it.

-

Risk Control: Optimization spots important parts and possible trouble spots. This helps in reducing risks linked to equipment problems. It keeps people safe and work on track.

10 Preventive Maintenance Management Planning Tips

Whether you have a small number of equipment or assets, it's crucial to keep them performing at their best. This applies to large numbers too. Equipment breakdowns can harm your profits. It can cause a complete stop in business operations.

Planning and scheduling preventive maintenance can help your maintenance team. It improves their equipment care skills. It can cut down on unexpected problems.

Here are some tips to enhance preventive maintenance planning:

-

Check Your Equipment -Examine your facility and equipment. Find out how many machines you have and how old they are. Learn the types of machines and their manufacturers. Look into past maintenance problems. This helps you understand your equipment's condition for better planning.

-

Check Repair Records - Go through repair records. Find patterns in equipment breakdowns. Consider factors like seasons, weather, and machine stress. This helps plan, buy parts, and manage resources more.

-

Establish Maintenance Standards -Collaborate with your maintenance team to create a plan. This plan must suit the whole organization. Set clear guidelines for performance and efficiency. Document processes, procedures, and schedules. Use CMMS software to create and manage checklists in work orders.

-

Focus on Tasks by Criticality - When scheduling preventive maintenance, differentiate tasks by importance. Do the critical tasks on time. Reschedule less critical tasks for later. CMMS software helps manage these tasks from anywhere.

-

Employee Training - Ensure technicians are well-trained in equipment operations and maintenance. Trained technicians can prevent major breakdowns by addressing issues. Keep training records in CMMS for easy management.

-

Spare Parts Inventory - Maintain an inventory of spare parts to handle breakdowns. CMMS provides historical data for better spare part planning.

-

Resource Management - Schedule preventive maintenance to align with resource availability. Off-peak scheduling saves time and money. CMMS assists in resource management.

-

Mobility - Manage maintenance data from anywhere with a CMMS. Gain flexibility and convenience in tracking maintenance activities on the go.

-

Reporting and Compliance - Use CMMS reporting tools to compile and convert data into useful reports. Show compliance with regulatory standards through these reports

-

KPI Dashboard - Create dashboards to get an overview of your CMMS data. View maintenance trends and priorities in a graphical format. Track your facility's performance and customize dashboards as needed.

Measuring Effectiveness of Preventive Maintenance Activities

To see if preventive maintenance works, follow its principles and ask these questions:

-

Do the activities meet the defined goal of preventive maintenance?

-

Ensure that the tasks are contributing to the equipment's reliability and longevity.

-

Are these activities preserving and protecting equipment capacity through a disciplined process?

-

Verify if the maintenance tasks are safeguarding the equipment's performance and functionality.

-

Do these activities produce the same desired outcomes?

-

Assess whether the maintenance tasks yield consistent results, minimizing variations and uncertainties.

-

If these activities fall short of meeting these criteria, why is that the case?

-

Identify the reasons behind any shortcomings or discrepancies in achieving the PMO objectives.

-

-

What strategies to put in place to meet these objectives?

-

Brainstorm and install improvements to align the activities with preventive maintenance goals.

Answering these questions will help improve your preventive maintenance processes.

Benefits of Preventive Maintenance Program

A well-optimized PM program design offers significant and diverse benefits. Here are the key advantages it offers:

-

Cost Savings: Optimized PM program lowers costs, prioritizing essential component care. This leads to less spending on spare parts, labour, and equipment repairs.

-

Improved Reliability: Optimization improves equipment reliability by addressing potential issues early. This results in smoother operations with fewer disruptions to production.

-

Extended Equipment Life: Regular maintenance prolongs equipment lifespan, reducing the need for replacements. It maximizes asset value, increases ROI, and avoids early retirement.

-

Data-Driven Decision Making: Optimization relies on data analysis for making informed choices. This data-driven approach enhances decision accuracy and reduces guesswork.

-

Operational Continuity: Optimization leads to reliable operations with less downtime. This helps meet production goals and keeps customers satisfied.

-

Improved Safety: Reliable equipment is safer to use. Optimization reduces the risk of accidents caused by equipment failures. This makes the workplace safer.

Preventive Maintenance Problems and Solutions

Doing preventive maintenance on equipment that keeps breaking down is insanity. Below are common issues with potential solutions that may arise in preventive maintenance:

1. Inspections

-

Problems

-

Tasks not addressing failure modes.

-

Ineffective measurements.

-

Lack of step-by-step procedures.

-

No verification of task completion.

-

Personnel not following procedures.

-

Solutions:

-

Engage maintenance technicians in evaluating tasks.

-

Display a graph comparing preventive maintenance labour hours to emergency labour hours.

2. Lubrication

-

Problems:

-

High variation in measurements.

-

Lack of best practices training.

-

Lack of oversight from maintenance leadership.

-

Solutions:

-

Determine the required grease type and amount.

-

Inspect lubrication processes.

3. Time-Based Change Outs

-

Problems:

-

Asset unavailability and rescheduling.

-

Ineffective planning and scheduling.

-

Solutions:

-

Provide planning and scheduling training for planners and leadership.

4. Operator Care

-

Problems:

-

Lack of preventive maintenance specifications.

-

No reporting for corrective action.

-

Lack of management support.

-

Solutions:

-

Measure the effectiveness of preventive maintenance compliance for operator care.

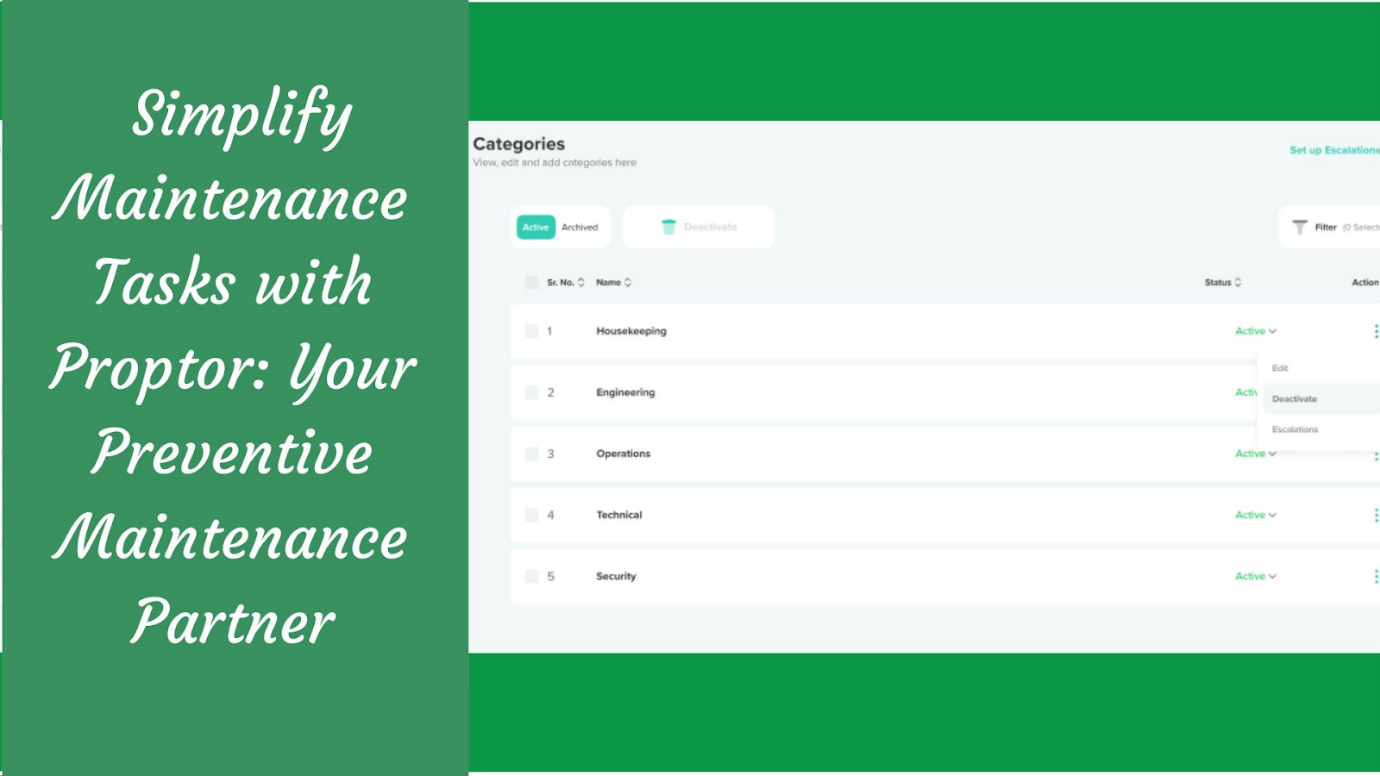

Partner with Proptor App to optimize efficiency

Proptor App can play a valuable role in preventive maintenance. It offers property owners with tools that help them handle and plan maintenance jobs. Here's how Proptor App helps in preventive maintenance:

- Maintenance Scheduling: Proptor App allows users to schedule regular maintenance tasks for properties. You can create checklists for maintenance tasks and choose when to do them. This makes sure that maintenance isn't forgotten, keeping timelines in mind.

-

Task Reminders: The app will alert maintenance managers with task reminders. This ensures preventive maintenance happens on schedule. It also reduces the chances of equipment problems or property issues.

-

Documentation: Proptor enables users to document maintenance activities. You can record details of maintenance work, including who is doing what. This documentation serves as a valuable record for future reference and auditing.

-

Inventory Management: Proptor have features for managing inventory. Users can use these to track spare parts and supplies necessary for maintenance.

-

Customized Checklists: Owners and managers can make special maintenance checklists. You can create it to match your property's particular requirements. This ensures that preventive maintenance tasks suit the property's requirements.

-

Reporting and Analytics: Proptor often provides reporting and analytics features. Users can create reports about maintenance tasks, expenses, and how the property is doing. This data helps in assessing the effectiveness of preventive maintenance efforts.

-

Communication: The app facilitates communication between property managers, maintenance teams, and even tenants. This can be essential for reporting maintenance issues and coordinating preventive maintenance tasks.

-

Historical Data: Proptor App stores historical data related to maintenance activities. Use this information to identify trends and track the performance of equipment. Make data-driven decisions for future preventive maintenance planning.

-

Integration with Service Providers: Proptor allow users to connect with service providers and contractors through the app. This streamlines the process of requesting and scheduling maintenance services.

-

Cost Tracking: Users can track the costs associated with preventive maintenance. This helps in budgeting for maintenance expenses and ensures cost-effectiveness.

Conclusion

In this article, we talked about why preventive maintenance is essential. It keeps equipment working well. We also talked about PMO, which makes maintenance even better using data and plans.

Preventive maintenance stops things from breaking down. It is better than fixing them after they break. There are two main types: Operator Checks. One, where operators do simple inspections, and Maintenance PMs. Other, where technicians do regular inspections to keep equipment in good shape.

Preventive Maintenance Optimization aims to improve preventive maintenance. It wants to be faster, have less downtime, use special plans, and handle risks well. For good preventive maintenance planning, remember to check equipment and repair history. Set standards and focus on important tasks. Train your employees, keep spare parts, manage resources, and be mobile. Reporting, following rules, and using KPI dashboards are important too.

To check if preventive maintenance works well, ask questions. Make sure it meets goals, keeps equipment working, and gives good results. If not, find ways to make it better.