5 strategies to prevent equipment failure

Madhurima Sanyal |

23 Jan 2024 |

04:10 AM

- Brief overview of the importance of preventing equipment failure.

- Common Causes of Equipment Failure

- Aging Equipment -Impact of age and wear on equipment

- Strategies to address aging equipment

- Operator Error - Providing adequate operator training

- Lack of Preventive Maintenance - Developing an effective preventive maintenance strategy

- Over-Maintenance - Discussing the pitfalls of excessive maintenance and Balancing maintenance efforts

- Failure to Monitor Equipment Condition - Importance of regular inspections and Embracing condition-based maintenance

- Maintenance Strategies

- Introduction to Proptor and its features

- 5 Strategies to Prevent Equipment Failure

- Conclusion

How CMMS create efficiencies during labor shortage?

Pratik Lohiya 28 Mar 2024 | 06:56 AMUnlocking operational efficiency and overcoming labor shortages with strategic CMMS adoption and management software integration....

Preventing equipment failure is paramount in maintaining operational efficiency and minimizing disruptions. In industrial settings, equipment breakdown can lead to costly downtime, negatively impacting production schedules and profitability. Proactive measures to prevent equipment failure not only save time and resources but also contribute to a safer working environment. This blog will delve into five strategies that organizations can implement to safeguard their critical assets and ensure uninterrupted workflow.

Brief overview of the importance of preventing equipment failure.

Understanding Equipment Failure

Equipment failure occurs when machinery or systems cease to perform their intended functions, jeopardizing productivity. It is a multifaceted issue with various causative factors, ranging from mechanical wear and tear to human errors. Recognizing the signs of potential failure is crucial for implementing preventive measures and reducing unplanned downtime.

Different types of equipment

Different types of equipment are susceptible to distinct failure modes. From heavy machinery in manufacturing plants to critical components in IT infrastructure, understanding the specific vulnerabilities of each type allows for targeted preventive strategies.

By addressing these vulnerabilities, organizations can extend the lifespan of equipment, reduce maintenance costs, and maintain a seamless operational workflow. In the upcoming sections, we will explore the common causes of equipment failure and effective strategies to prevent them.

Common Causes of Equipment Failure

In the intricate landscape of machinery and technology, equipment failure is an inevitable challenge that organizations face. Understanding the common causes behind these failures is paramount for mitigating risks, optimizing performance, and ensuring the longevity of critical assets.

Aging Equipment -Impact of age and wear on equipment

As equipment ages, wear and tear become inevitable adversaries, posing significant challenges to its reliability. Components degrade over time, leading to diminished performance and an increased risk of failure. Understanding the impact of aging on equipment is essential for devising proactive maintenance strategies. Regular assessments, performance monitoring, and timely replacement of worn components are vital steps to mitigate the adverse effects of aging and equipment failures.

Strategies to address aging equipment

To combat the challenges posed by aging equipment, organizations can implement strategic measures. Predictive maintenance, which involves monitoring equipment performance using advanced analytics, allows for the identification of potential issues before they escalate. Additionally, investing in quality components, conducting regular inspections, and adhering to a well-defined preventative maintenance plan contribute to extending the lifespan of equipment.

Operator Error - Providing adequate operator training

Human errors remain a leading cause of equipment failures. Inadequate training or lack of awareness among operators can result in incorrect usage, mishandling, and, ultimately, equipment breakdowns. Providing comprehensive operator training is a proactive approach to minimize the risk of errors.

It is important to understand the significance of training programs, detailing the key elements required for effective operator education. By investing in adequate training, organizations can empower their maintenance team to operate equipment safely and proficiently and reduce unplanned downtime.

Lack of Preventive Maintenance - Developing an effective preventive maintenance strategy

Neglecting preventive maintenance is a common pitfall that significantly contributes to equipment failures. An effective preventative maintenance strategy involves systematically scheduled inspections, repairs, and component replacements to address potential issues before they escalate.

This section emphasizes the importance of preventive maintenance in prolonging equipment lifespan and minimizing unplanned downtime. It will also provide practical insights into developing a customized preventative maintenance plan tailored to the specific needs of different equipment types and industries.

Over-Maintenance - Discussing the pitfalls of excessive maintenance and Balancing maintenance efforts

While maintenance is crucial for equipment reliability, excessive or unnecessary maintenance can be counterproductive. Over-maintenance not only incurs unnecessary costs but can also accelerate wear on components. Achieving a balance in maintenance efforts is key to maximizing equipment lifespan and minimizing costs.

This section delves into the risks associated with over-maintenance, offering guidance on finding the right balance. By adopting a data-driven approach and leveraging modern maintenance management practices, organizations can optimize their maintenance efforts for optimal equipment performance.

Failure to Monitor Equipment Condition - Importance of regular inspections and Embracing condition-based maintenance

Regularly monitoring the condition of equipment is essential for identifying potential issues before they escalate into failures. This section highlights the significance of routine inspections and how embracing this strategy can revolutionize equipment reliability.

Leveraging technology, such as sensors and predictive analytics, enables real-time monitoring, allowing organizations to detect anomalies and proactively address issues. By integrating condition-based maintenance into their strategies, businesses can enhance equipment performance, schedule equipment maintenance tasks effectively and minimize the risk of equipment downtime.

Maintenance Strategies

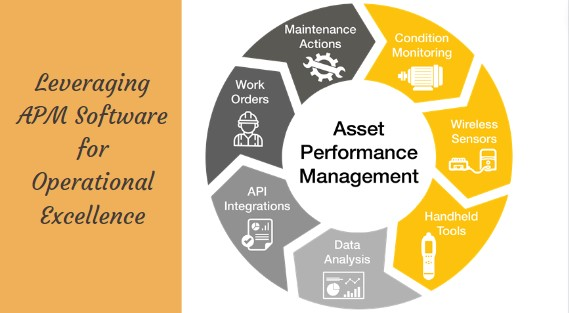

Overview of maintenance management software

In the digital age, embracing technology is paramount for effective equipment maintenance. Maintenance Management Software has emerged as a game-changer in optimizing maintenance processes. This section provides a comprehensive overview of this software, exploring its functionalities, benefits, and its role in preventing causes of equipment failure.

From streamlining work orders to facilitating predictive maintenance, Maintenance Management Software empowers organizations to enhance their overall maintenance strategy. The incorporation of such software ensures a more efficient and proactive approach to equipment care, ultimately reducing downtime and increasing efficiency.

Run-to-failure maintenance vs. preventive maintenance

Choosing the right proactive strategy is pivotal in determining the longevity and reliability of equipment. This section delves into the fundamental differences between two prominent approaches: Run-to-Failure Maintenance and Preventive Maintenance. Run-to-Failure, though cost-effective in the short term, can lead to unplanned downtime and increased repair costs.

On the other hand, Preventive Maintenance involves scheduled inspections and repairs, addressing potential issues before they result in failures. The section evaluates the pros and cons of each strategy, guiding readers in making informed decisions based on their equipment types, industry, and operational requirements.

The role of preventive maintenance in reducing failures

Preventive maintenance stands as a proactive and strategic approach to equipment care, playing a pivotal role in minimizing failures and extending the lifespan of machinery. This section explores how preventive yet routine maintenance tasks serves as a critical element in reducing the risk of machine failure.

By implementing a regular maintenance schedule of inspections, repairs, and component replacements, organizations can address potential issues before they escalate into failures. The focus is on maintaining equipment at optimal operating conditions, ensuring that components are in peak performance and reducing the likelihood of wear-related failures.

Overcoming challenges with effective strategies

While preventive maintenance is a powerful strategy, it comes with its own set of challenges. This section explores common hurdles organizations may face when implementing preventaYive maintenance and provides effective strategies to overcome them.

One challenge is developing a customized preventative maintenance plan tailored to the specific needs of diverse equipment. This section guides readers on creating a robust plan by leveraging industry best practices and considering the unique requirements of each machine.

Another challenge lies in establishing a routine that balances maintenance efforts without being excessive. By addressing these challenges head-on and implementing effective strategies, organizations can unlock the full potential of preventative maintenance, ensuring optimized maintenance practices.

Introduction to Proptor and its features

Meet Proptor, the cutting-edge solution designed to revolutionize equipment maintenance. Proptor is a comprehensive maintenance management software that goes beyond the conventional, offering a suite of features to avoid frequent repairs and streamline maintenance program.

Proptor's user-friendly interface provides a centralized platform for managing work orders, tracking maintenance activities, and scheduling preventive tasks effortlessly. The software empowers maintenance teams with real-time insights, allowing them to make data-driven decisions to prevent equipment malfunctions.

5 Strategies to Prevent Equipment Failure

Provide Adequate Operator Training - Importance of operator training and Key elements

Human factor is pivotal when it comes to preventing equipment failures. This strategy underscores the critical importance of providing comprehensive operator training. Properly trained operators contribute significantly to the asset lifespans of equipment by minimizing the risk of human error and mishandling.

Key elements of effective training programs include in-depth equipment knowledge, safety protocols, and hands-on simulations. By investing in operator education, organizations not only enhance workplace safety but also ensure that equipment is utilized proficiently, mitigating the potential for unexpected downtime.

Develop an Effective Preventive Maintenance Strategy - Crafting a preventative maintenance plan

Crafting a robust preventive maintenance plan is a cornerstone in the arsenal against equipment failures. This strategy involves systematically scheduling inspections, repairs, and component replacements to address potential issues before they escalate.

The plan should be tailored to the specific needs of different equipment types and industries, incorporating industry best practices. A well-crafted preventive maintenance strategy not only extends the lifespan of equipment but also minimizes unexpected breakdowns, ultimately saving costs and ensuring operational continuity.

Perform Regular Inspections - Role of inspections in preventing failures

Regular inspections play a crucial role in preventing equipment failures by detecting potential issues before they compromise performance. This strategy involves setting up a systematic inspection process that includes thorough examinations of equipment components. By incorporating regular inspections into the maintenance routine, organizations can address minor concerns proactively, preventing them from evolving into major failures that disrupt operations.

Implementing Condition-Based Maintenance

A forward-thinking approach to equipment maintenance involves embracing condition-based maintenance. This strategy utilizes real-time data from sensors and other monitoring tools to assess the actual condition of equipment.

By continuous monitoring and detecting anomalies, organizations can predict when maintenance is truly needed, allowing for targeted interventions. This section explores the benefits of condition-based maintenance in maximizing equipment reliability, minimizing unscheduled downtime, and optimizing maintenance efforts.

Invest in Maintenance Management Software

As technology continues to advance, Maintenance Management Software emerges as a game-changer in the fight against equipment failures. This strategy involves integrating the software into the maintenance workflow to streamline operations. The software includes work order management, preventive maintenance scheduling, and real-time analytics. By investing in this software, organizations can enhance overall maintenance efficiency, reduce administrative complexities, and take a proactive stance in preventing machine failure.

Conclusion

The proactive implementation of operator training, preventive maintenance, regular inspections, condition-based maintenance, and investment in Maintenance Management Software constitutes a robust defense against equipment failures. By prioritizing these strategies, organizations not only enhance equipment reliability but also foster a culture of efficiency and safety. Embracing these proper maintenance measures helps to minimize equipment failure, stops production interruptions and ensures sustained operational excellence.