Guide to Use Maintenance Software to Cut Costs

Madhurima Sanyal |

03 Feb 2024 |

04:26 AM

- Importance of Maintenance Software in Cost Reduction

- Overview of the Benefits of Using Maintenance Software

- Definition and Purpose of Maintenance Software

- Assessing Your Maintenance Needs

- Selecting the Right Maintenance Software Solution

- Comparing Different Options and Their Features

- Implementing Maintenance Software system

- What Does Software Maintenance Include?

- Why Are Software Maintenance Services Essential for Businesses?

- Factors Affecting Software Maintenance Costs

- 8 Ways to Use Digital Maintenance Solutions to Control Costs

- Choosing the Right Facility Management Software

- What's a CMMS? Discover the Benefits, Use & Cost

- Conclusion

Top 7 Building Maintenance Softwares

Madhurima Sanyal 31 May 2024 | 11:55 AMDiscover the top 7 building maintenance software of 2024. Learn about their features, pricing, and why Proptor stands out as a leading solution in operations management. ...

Effective maintenance management is significant for operational success, and leveraging maintenance software has become imperative for organizations aiming to streamline processes and cut costs. This comprehensive guide explores into the intricacies of utilizing maintenance software strategically, shedding light on its pivotal role in achieving tangible financial savings.

Importance of Maintenance Software in Cost Reduction

By seamlessly integrating preventive maintenance tasks, companies can mitigate unexpected breakdowns and extend the lifespan of their assets. This not only minimizes downtime costs but also enhances overall operational efficiency.

The ability to schedule preventive maintenance, backed by digital maintenance solutions, allows businesses to proactively address potential issues before they escalate, resulting in substantial cost savings.

Overview of the Benefits of Using Maintenance Software

The benefits of incorporating maintenance software extend beyond mere cost reduction. These robust systems empower organizations with enhanced asset management capabilities, offering real-time insights into the health and performance of critical assets.

With features like predictive maintenance, companies can transition from reactive approaches to a more proactive stance, minimizing maintenance costs and maximizing asset lifespan. Additionally, maintenance software streamlines workflows, improves resource allocation, and contributes to a culture of continuous improvement.

Definition and Purpose of Maintenance Software

Maintenance software, often referred to as Computerized Maintenance Management System (CMMS), serves as a centralized hub for managing, tracking, and optimizing maintenance activities. Its primary purpose is to digitize and streamline the entire maintenance workflow, from work order management to preventive maintenance scheduling.

By automating routine tasks and providing data-driven insights, maintenance software empowers organizations to make informed decisions, reduce downtime, and ultimately achieve significant savings in maintenance costs.

Assessing Your Maintenance Needs

Assessing your maintenance needs is a crucial first step toward achieving operational excellence and cost efficiency. Organizations must conduct a comprehensive evaluation to understand the intricacies of their maintenance requirements. This involves scrutinizing existing maintenance processes, identifying pain points, and recognizing areas where optimization can lead to substantial cost reductions

Evaluating Your Organization's Maintenance Requirements

Evaluating maintenance requirements involves a meticulous examination of the entire spectrum of assets, equipment, and facilities under an organization's purview. Asset management software plays a pivotal role in this process, providing a holistic view of asset health, performance history, and maintenance schedules.

By leveraging this technology, organizations can transition from reactive to proactive maintenance strategies, minimizing unplanned downtime and associated costs.

Identifying Key Areas Where Costs Can Be Reduced Through Software Implementation

Identifying key areas for cost reduction necessitates a keen focus on streamlining maintenance operations. The implementation of computerized maintenance management systems (CMMS) or maintenance management software is instrumental in achieving this goal.

These systems offer a centralized platform for managing work orders, tracking maintenance activities, and optimizing resource allocation. Maintenance software programs enhance the efficiency of maintenance managers, allowing them to prioritize tasks, allocate resources judiciously, and ultimately reduce operational costs.

Incorporating enterprise asset management further extends the scope of cost reduction efforts. This strategic approach encompasses a comprehensive view of assets across the entire organization, aligning maintenance activities with overarching business goals. Facilities management software, integrated within the maintenance framework, ensures that all aspects of the organizational infrastructure are considered, enhancing the effectiveness of the maintenance strategy.

Selecting the Right Maintenance Software Solution

Choosing the optimal maintenance software solution is a pivotal decision that significantly influences an organization's efficiency, cost-effectiveness, and overall operational success.

Factors to Consider When Choosing a Maintenance Software Solution

Maintenance Management Software: Embracing a dedicated maintenance management software is essential. This tool centralizes all standard operating procedures, providing a unified platform for work order management, asset tracking, and preventive maintenance scheduling. Such comprehensive solutions contribute to a streamlined workflow, reducing downtime and maintenance costs.

Maintenance Software Program: The chosen maintenance software program should align seamlessly with the organization's existing processes. Customization features play a crucial role in tailoring the software to specific needs, ensuring it complements the unique maintenance requirements of the business.

Maintenance Processes: A robust maintenance software solution should enhance existing processes rather than disrupt them. Integration with current workflows, from work order initiation to completion, is crucial for fostering a smooth transition and maximizing the efficiency gains offered by the software.

Quality Maintenance Software Plan: A well-structured and quality maintenance software plan is fundamental. It involves outlining clear objectives, defining key performance indicators (KPIs), and establishing measurable goals. This plan serves as a roadmap for successful software implementation and ongoing maintenance strategy improvement.

Asset Management Software: Asset management is a key facet of maintenance, and the software chosen should excel in this domain. The integration of asset management features ensures comprehensive visibility into asset health, facilitating proactive maintenance and minimizing overall maintenance costs.

Preventive Maintenance: An effective maintenance software solution should empower organizations to implement preventive maintenance strategies. This involves scheduling routine maintenance tasks based on asset performance data, preventing unexpected breakdowns, and reducing reactive maintenance costs.

Maintenance Costs: Last but not least, the cost-effectiveness of the chosen solution is critical. Assessing both the upfront costs and potential long-term savings is essential. A well-chosen maintenance software solution should provide a positive return on investment by reducing overall maintenance costs and improving operational efficiency.

Comparing Different Options and Their Features

When it comes to implementing maintenance software, a crucial phase involves comparing different options and their features. The right choice can significantly impact an organization's efficiency, cost-effectiveness, and overall maintenance management.

To streamline this decision-making process, it's essential to consider the specific needs of the organization and evaluate how each maintenance software option aligns with those requirements. Here are key factors to consider:

Comparing Different Options and Their Features

When it comes to implementing maintenance software, a crucial phase involves comparing different options and their features. The right choice can significantly impact an organization's efficiency, cost-effectiveness, and overall maintenance management.

To streamline this decision-making process, it's essential to consider the specific needs of the organization and evaluate how each maintenance software option aligns with those requirements. Here are key factors to consider:

-

Maintenance Management Software: The heart of effective maintenance lies in dedicated maintenance management software. Compare various options in terms of their capabilities to manage work orders, track assets, and support preventive maintenance. Look for intuitive interfaces that enhance user experience and contribute to the overall efficiency of maintenance teams.

-

Maintenance Software Program: Assess the features offered by different maintenance software programs. Look for flexibility and scalability, ensuring that the chosen program can adapt to the evolving needs of the organization.

-

Maintenance Processes: The selected software should seamlessly integrate with existing maintenance processes. Evaluate how each option handles workflow management, from initiating work orders to tracking activities. The goal is to enhance, not disrupt, the established processes for a smooth transition.

-

Quality Maintenance Software Plan: Consider the support provided for implementing a quality maintenance software plan. Look for options that offer comprehensive training, documentation, and ongoing support. A well-supported implementation plan contributes to the successful adoption of the software across maintenance teams.

-

Corrective Maintenance: Evaluate how each software option handles corrective maintenance. The ability to quickly respond to unplanned issues is crucial. Look for features that facilitate rapid identification, assignment, and resolution of corrective maintenance tasks, minimizing downtime and associated maintenance costs.

-

Maintenance Team and Teams: Consider the user-friendliness of the software for both individual maintenance team members and broader teams. User adoption is key to the success of the software implementation. Choose options that offer collaborative features, making it easy for maintenance teams to work together efficiently.

Implementing Maintenance Software system

Successfully implementing a maintenance software system necessitates a meticulous approach. This involves developing a comprehensive plan that outlines specific goals, assigns responsibilities, and establishes a well-defined timeline for the software rollout. Additionally, engaging key stakeholders, including maintenance managers and team leaders, is crucial for obtaining the necessary buy-in.

Clear communication of the software's benefits and addressing any concerns ensures a smooth transition. Furthermore, emphasizing the positive impact on daily tasks and overall efficiency is key to garnering support and enthusiasm from stakeholders, fostering a successful adoption of the maintenance software.

What Does Software Maintenance Include?

Software maintenance is a comprehensive process vital for sustaining optimal performance and functionality. It encompasses various activities aimed at enhancing, updating, and fine-tuning the software throughout its lifecycle.

Key components include regular updates to address bugs, glitches, or compatibility issues, implementing enhancements to improve features and capabilities, and providing ongoing technical support to ensure seamless operations. By addressing these aspects, software maintenance ensures that the system evolves to meet changing needs, remains secure, and continues to deliver value to the business.

Why Are Software Maintenance Services Essential for Businesses?

Software maintenance services play a crucial role in sustaining the health and efficiency of business operations. This is evident through several fundamental aspects:

Enhanced Performance

Regular updates and enhancements contribute to the enhanced performance of software. This ensures that the system operates at its optimum, minimizing downtime and disruptions, and ultimately leading to increased productivity across various business functions.

Security

Security is paramount in today's digital landscape. Software maintenance services include the implementation of security patches and updates to safeguard against evolving threats. This proactive approach mitigates vulnerabilities, protecting sensitive data and maintaining the integrity of the software ecosystem.

Adaptability

As business needs evolve, so should the software. Maintenance services ensure that the software remains adaptable and compatible with the latest technologies and industry standards. This adaptability is vital for business continuity and staying competitive in dynamic markets.

User Satisfaction

Ultimately, software maintenance services contribute to user satisfaction. Regular updates, security measures, and adaptability translate into a smoother and more reliable user experience. Satisfied users are more likely to be productive and engaged, fostering a positive impact on overall business performance.

Factors Affecting Software Maintenance Costs

Software maintenance costs are influenced by a myriad of factors, both technical and non-technical, which collectively determine the efficiency and effectiveness of the maintenance process.

Technical Factors

Dependency on External Systems

Software rarely operates in isolation; it often relies on external systems for data exchange or integration. The degree of dependency on these external systems can significantly impact maintenance costs. Changes or updates in external systems may necessitate adjustments in the software, leading to additional development and testing efforts. Implementing robust integration mechanisms and staying informed about external system changes are key strategies to manage this factor efficiently.

Quality of Initial Development

The quality of the initial software development sets the foundation for ongoing maintenance. Well-structured, modular code developed following industry best practices tends to be more maintainable. High-quality coding practices reduce the likelihood of introducing bugs during updates and make it easier to implement new features or modifications. Investing in rigorous testing and code review processes during the initial development phase can contribute to long-term cost savings in maintenance.

Regulatory Compliance

In regulated industries, compliance with specific standards is mandatory. Ensuring regulatory compliance is a continuous process that affects maintenance costs. Regular updates may be required to align the software with evolving regulatory standards. Non-compliance can result in legal consequences, fines, and damage to the organization's reputation. Prioritizing a proactive approach to regulatory compliance can help mitigate risks and associated costs.

Non-Technical Factors

Cost-Effective Maintenance Strategies:

The chosen maintenance strategy significantly impacts costs. Reactive approaches may lead to higher expenses due to unplanned downtime and emergency fixes. Implementing proactive strategies, such as preventative maintenance and scheduled updates, can minimize unexpected costs and contribute to overall efficiency.

Dependency on Existing Systems:

Software rarely operates in isolation; it interacts with existing systems within an organization. Compatibility and integration challenges with legacy systems may elevate maintenance costs. A strategic approach to system integration and periodic evaluations can help manage these dependencies effectively.

8 Ways to Use Digital Maintenance Solutions to Control Costs

Control Backlogs

Digital maintenance solutions, particularly work order management software, enable organizations to streamline task prioritization and allocation. By efficiently managing work orders, backlogs are reduced, preventing delays and ensuring that maintenance tasks are addressed promptly. This proactive approach minimizes downtime and associated costs.

Create a Mobile Hub for Information

Mobility is key in modern maintenance strategies. Utilizing mobile-friendly software solutions facilitates on-the-go access to critical information. Facility maintenance department equipped with mobile hubs can instantly retrieve work orders, access asset details, and input real-time updates, enhancing overall efficiency and reducing delays.

Reduce Scrap and Rework

Digital solutions contribute to improved preventive maintenance strategies, minimizing unexpected breakdowns. By addressing potential issues before they escalate, organizations can reduce the need for costly scrap and rework. This proactive stance not only controls costs but also extends the lifespan of physical assets.

Determine Repair or Replace

Digital maintenance solutions provide data-driven insights into asset performance. By analyzing historical data and trends, organizations can make informed decisions about whether to repair or replace equipment. This decision-making precision minimizes unnecessary expenses and ensures optimal resource allocation.

Calculating Important KPIs

Key Performance Indicators (KPIs) are integral for assessing maintenance efficiency. Digital solutions facilitate the calculation and monitoring of crucial KPIs, such as mean time to repair (MTTR) and overall equipment effectiveness (OEE). By tracking these metrics, organizations can pinpoint areas for improvement and enhance overall maintenance efficiency.

See Trends in Asset Costs

Digital solutions provide a comprehensive view of asset performance and associated costs over time. Identifying trends in asset costs allows organizations to predict potential maintenance expenses, facilitating budgetary planning and enabling proactive cost control measures.

Reduce Energy Consumption

Facility maintenance often involves managing energy-consuming systems. Digital solutions enable organizations to monitor and optimize energy usage, identifying areas where consumption can be reduced without compromising operational efficiency. This contributes to both cost savings and sustainability efforts.

Make Smart Inventory Decisions

Efficient inventory management is crucial for controlling costs. Digital solutions, integrated with inventory management features, enable organizations to track and manage spare parts effectively. This ensures that inventory levels are optimized, minimizing unnecessary expenditures on excess stock while avoiding shortages that can lead to downtime.

Choosing the Right Facility Management Software

Selecting an effective facility management software is paramount for optimizing maintenance operations. Consider software solutions that integrate seamlessly with your organization's maintenance strategy. Look for features such as work order management, preventive maintenance scheduling, and real-time asset tracking. The right facility management software enhances overall maintenance efficiency, streamlining processes to improve maintenance program.

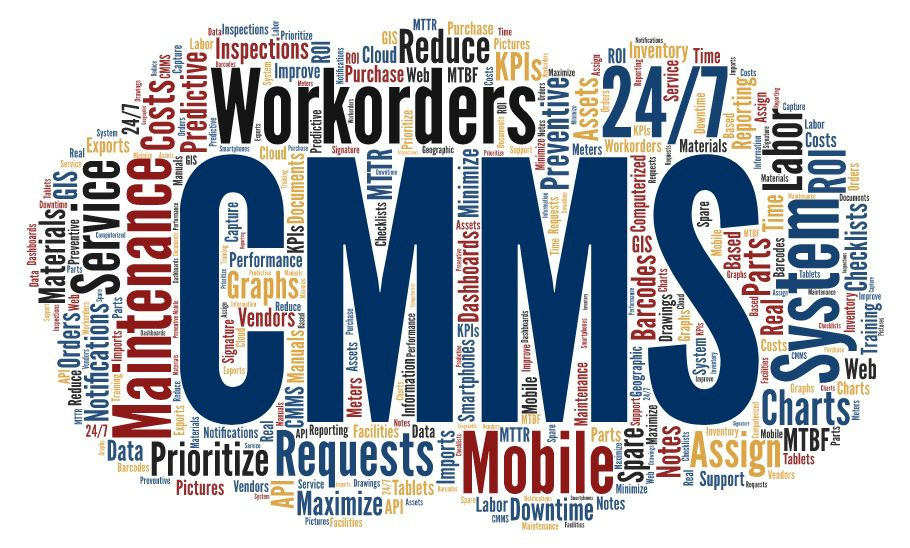

What's a CMMS? Discover the Benefits, Use & Cost

A Computerized Maintenance Management System (CMMS) is a powerful tool for maintenance efficiency. It centralizes work orders, tracks asset information, and schedules preventive maintenance tasks. CMMS improves organization, reduces downtime, and extends the lifespan of physical assets. While costs vary, the benefits in enhanced maintenance strategy and operational efficiency far outweigh the investment.

Understanding the Basics of Maintenance Software

Maintenance software is the backbone of streamlined facility maintenance. It encompasses various tools and solutions designed to optimize maintenance processes. From work order management software to preventive maintenance features, understanding the basics is crucial for implementing a cohesive and effective maintenance strategy.

Common CMMS Features and Functionalities

Common features of a CMMS include work order creation, asset tracking, and preventive maintenance scheduling. These functionalities ensure a systematic approach to maintenance tasks, reducing downtime and improving overall efficiency. Familiarize yourself with these features to leverage the full potential of your CMMS for enhanced maintenance strategies.

Benefits of Facility Management Software's features

Implementing facility management software offers numerous benefits. It centralizes maintenance tasks, improves asset visibility, and enhances preventive maintenance. The result is improved maintenance efficiency, reduced downtime, and increased overall operational productivity. The investment in quality facility management software pays off through long-term cost savings and optimized facility maintenance.

Conclusion

In facility maintenance, the pursuit of improved maintenance efficiency is paramount for sustainable success. The integration of cutting-edge software solutions, such as robust work order management software, has emerged as a pivotal strategy in achieving this objective. By aligning with a well-defined maintenance strategy, organizations can harness the power of digital tools to optimize their operations and enhance overall efficiency.

Effective facility maintenance goes beyond merely addressing issues reactively; it involves a proactive approach, leveraging preventive strategies and real-time asset tracking. The careful selection of software solutions that cater to the unique needs of an organization forms the cornerstone of this transformative journey.

Central to this landscape is the understanding and implementation of Computerized Maintenance Management Systems (CMMS). The benefits, utility, and associated costs make CMMS a key player in the pursuit of streamlined maintenance operations. The integration of CMMS empowers organizations to centralize work orders, track physical assets, and implement preventive maintenance scheduling, ultimately contributing to improved maintenance efficiency.

As we delve into the basics of maintenance software, it becomes evident that these tools are not mere conveniences but strategic necessities in contemporary facility management. From preventive maintenance features to the dynamic capabilities of work order management software, each element plays a crucial role in shaping a comprehensive and effective maintenance strategy.

In the exploration of common CMMS features and functionalities, the emphasis is on understanding how these tools work in unison to create a systematic and efficient approach to maintenance tasks. By grasping the intricacies of CMMS, organizations can unlock its full potential to reduce downtime, enhance asset management, and, in essence, supercharge maintenance efficiency.

The benefits derived from the implementation of facility management software are multi-faceted. From centralizing maintenance tasks to improving asset visibility, the impact is substantial. The ripple effect is felt in reduced downtime, increased operational productivity, and, perhaps most importantly, the ability to navigate facility maintenance challenges with agility and precision.

The investment in software solutions tailored for facility maintenance is an investment in the operational resilience and long-term success of any organization. The journey to improve maintenance efficiency is an ongoing one, and with the right tools and strategies in place, organizations can not only meet the demands of today but also prepare for the challenges of tomorrow. As technology continues to evolve, the integration of sophisticated software solutions will remain a cornerstone in the ever-advancing landscape of facility maintenance.