What is Fault Tree Analysis

Viki Dongare |

05 Mar 2024 |

07:37 AM

- Who Uses Fault Tree Analysis?

- How is Fault Tree Analysis Performed?

- Understanding Fault Tree Analysis Symbols

- Empowering Your Maintenance Team with Fault Tree Analysis

- Uses of Fault Tree Analysis

- Advantages and Disadvantages of Fault Tree Analysis

- Components of Fault Tree Analysis

- Integration with CMMS (Computerized Maintenance Management System)

- Digitizing Work Processes with Fault Tree Analysis

- 6 Steps to Conduct Fault Tree Analysis (FTA)

- Conclusion

Best 7+ Home Inspection Report Software To Use in 2024

Madhurima Sanyal 24 May 2024 | 16:52 PMExplore the best home inspection report software of 2024. Discover features that make these top 7 tools indispensable for inspectors....

Introduction to Fault Tree Analysis

Fault Tree Analysis (FTA) is a systematic and graphical approach used to analyze potential causes of system failures. It involves breaking down complex systems into smaller components and analyzing component failures can lead to an undesired event, such as system failures. The fault tree diagram serves as a visual representation, with basic events representing individual failure modes and logic gates indicating the relationships between these events.

FTA plays a crucial role in maintenance management by providing a structured method to identify and prioritize potential failure scenarios, allowing maintenance teams to proactively address risks and minimize downtime. Understanding FTA is essential for organizations seeking to enhance their maintenance strategies and ensure the reliability and safety of their systems.

Who Uses Fault Tree Analysis?

Target Audience and Applications - Fault Tree Analysis (FTA) is widely utilized across various industries and disciplines, including aerospace, automotive, nuclear, and manufacturing. Maintenance managers, reliability engineers, safety professionals, and risk analysts are among the primary users of FTA. They employ this method to identify potential failure modes, assess system vulnerabilities, and develop strategies to mitigate risks.

Also, regulatory bodies often require the use of FTA in industries where safety is paramount, such as nuclear power plants and aviation. Furthermore, FTA finds applications in research and development, where it helps engineers design robust and reliable systems. Overall, anyone involved in ensuring the safety, reliability, and performance of complex systems can benefit from utilizing Fault Tree Analysis as a powerful tool in their decision-making process.

How is Fault Tree Analysis Performed?

Step-by-Step Guide - Fault Tree Analysis (FTA) is performed through a systematic process aimed at identifying and analyzing potential causes of equipment failure.

Overview of the Process:

-

Identification of System Failure: Begin by clearly defining the undesired event or system failure that needs to be analyzed.

-

Decomposition of System: Break down the system into its constituent components, including subsystems, equipment, and processes.

-

Identification of Basic Events: Identify the basic event or individual component failure modes that could contribute to the undesired event.

-

Construction of Fault Tree Diagram: Create a graphical representation using logic gates to depict the relationships between the basic events and the specific undesired event.

-

Analysis of Fault Tree: Evaluate the fault tree diagram to assess the probability and criticality of different failure scenarios.

-

Risk Mitigation Strategies: Based on the analysis, develop strategies to mitigate identified risks and prevent system level failures.

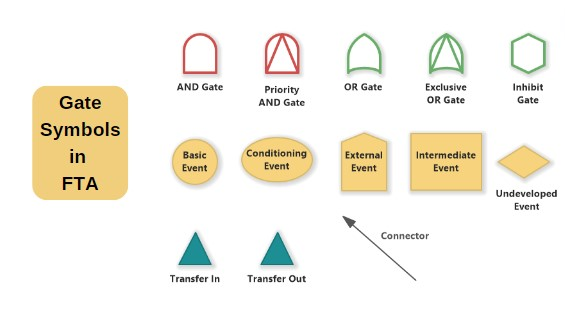

Understanding Fault Tree Analysis Symbols

Event Symbols

Event symbols in FTA represent the basic events or individual failure modes within a system. These events are depicted as circles or ovals in the fault tree diagram. Each event symbol corresponds to a specific failure scenario that contributes to the top event or undesired outcome.

Gate Symbols

Gate symbols in FTA represent logical relationships between events. These gates include AND, OR, and NOT gates, which depict how events combine to contribute to the occurrence of the top event. The AND gate indicates that all input events must occur for the output event to happen, while the OR gate signifies that any input event can lead to the output event. The NOT gate represents the absence of an event as a contributing factor.

Empowering Your Maintenance Team with Fault Tree Analysis

Enhancing Problem-Solving Capabilities - Empowering your maintenance team with Fault Tree Analysis (FTA) equips them with powerful problem-solving capabilities and enables proactive measures to prevent potential failures. By utilizing FTA, maintenance professionals can systematically analyze complex systems and identify critical failure modes or basic events that may lead to system breakdowns.

Preventing Potential Failures - This proactive approach allows teams to anticipate and mitigate risks before they escalate into costly failures, thereby minimizing downtime and maximizing operational efficiency. FTA also fosters a culture of continuous improvement within maintenance teams, as it encourages the identification of root causes and the development of targeted solutions. Overall, integrating FTA into maintenance management practices empowers teams to make informed decisions, prioritize resources effectively, and uphold system safety and reliability standards.

Uses of Fault Tree Analysis

Efficiency and Effectiveness

FTA streamlines the identification and analysis of potential failure modes within complex systems, allowing maintenance teams to focus their efforts on critical areas. By breaking down system component and analyzing their interactions, FTA enables teams to prioritize maintenance tasks and allocate resources more efficiently.

FTA facilitates proactive risk management by identifying root causes of failure events before they occur. This proactive approach minimizes downtime, reduces maintenance costs, and enhances overall system reliability. Additionally, FTA provides valuable insights into the effectiveness of existing maintenance strategies, allowing for continuous improvement and optimization of maintenance practices.

Overall, the utilization of Fault Tree Analysis in maintenance management leads to improved operational efficiency, enhanced system reliability, and ultimately, increased safety for personnel and assets.

Advantages and Disadvantages of Fault Tree Analysis

Pros and Cons Assessment

Fault Tree Analysis (FTA) offers several advantages in system analysis and risk management. It provides a systematic approach to identifying and analyzing potential failure modes, allowing for proactive risk mitigation strategies. FTA also offers a visual representation of complex systems, making it easier to communicate and understand potential failure scenarios. Additionally, FTA can be used to prioritize maintenance efforts and allocate resources effectively.

Critical Evaluation

However, there are also some limitations to consider. FTA requires expertise in system modeling and analysis, which may pose challenges for organizations lacking specialized skills. Additionally, FTA assumes independence between events, which may not always reflect real-world scenarios accurately. Furthermore, constructing comprehensive fault tree diagrams can be time-consuming and resource-intensive.

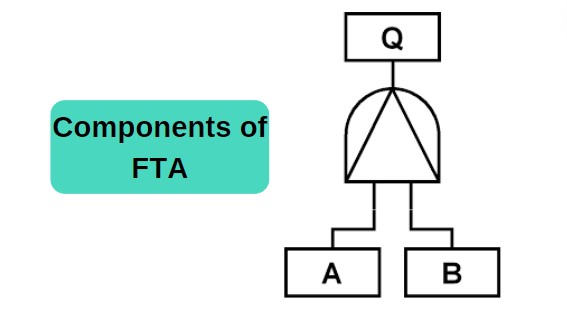

Components of Fault Tree Analysis

Understanding the Framework

Fault Tree Analysis (FTA) comprises several key components that form the framework for analyzing and understanding system failures.

Key Elements:

Fault Tree Diagram - The fault tree diagram is a graphical representation of the relationships between various events and the top event or undesired outcome. It visually depicts how basic events, intermediate events, and logic gates combine to contribute to system failure.

The Events - Events in FTA represent different failure modes or conditions within the system. Event tree analysis include basic events, which are individual failure mode, and intermediate events, which are combinations of basic events or other intermediate events.

Logic Gates - Logic gates in FTA represent the logical relationships between events. Common logic gates include AND gates, OR gates, and NOT gates. These gates determine how events combine to contribute to the top event. For example, an AND gate indicates that all input events must occur for the output event to happen, while an OR gate signifies that any input event can lead to the output event.

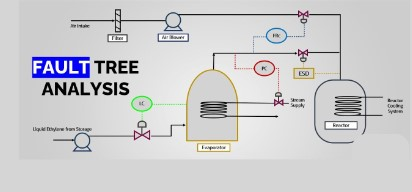

Integration with CMMS (Computerized Maintenance Management System)

Integrating Fault Tree Analysis (FTA) with a Computerized Maintenance Management System (CMMS) can significantly enhance maintenance processes and streamline operations. By leveraging technology, organizations can seamlessly incorporate FTA into their maintenance management workflows, allowing for more efficient identification and analysis of potential failure modes.

Leveraging Technology for FTA - CMMS provides a centralized platform for collecting and analyzing maintenance data, making it easier to perform FTA on complex existing systems. It enables maintenance teams to track failure probabilities, analyze fault tree analysis diagram, and identify contributing factors more effectively. Moreover, CMMS facilitates root cause analysis by providing access to historical maintenance records and enabling data-driven decision-making.

By integrating FTA with CMMS, organizations can proactively address maintenance issues, reduce downtime, and optimize resource allocation. This streamlined approach to maintenance management ensures that maintenance efforts are focused on mitigating risks and improving system reliability, ultimately leading to increased operational efficiency and cost savings.

Digitizing Work Processes with Fault Tree Analysis

Digitizing work processes with Fault Tree Analysis (FTA) involves transitioning from traditional paper-based methods to digital solutions, leading to significant efficiency gains in maintenance management.

Transitioning to Digital Solutions

By adopting digital tools and software platforms, organizations can streamline the entire FTA process, from data collection to analysis and reporting. Digital solutions allow for real-time collaboration among team members, enabling remote participation and faster decision-making. Moreover, digitization eliminates the need for manual data entry and reduces the risk of errors, ensuring the accuracy and reliability of FTA results.

Harnessing Efficiency Gains

Furthermore, digital platforms often offer advanced features such as predictive analytics and machine learning algorithms, enhancing the predictive capabilities of FTA models. These capabilities enable maintenance teams to identify potential failure modes more accurately and proactively address maintenance issues before they escalate.

Overall, digitizing work processes with Fault Tree Analysis empowers organizations to harness efficiency gains, optimize maintenance workflows, and improve overall system reliability and safety.

6 Steps to Conduct Fault Tree Analysis (FTA)

Guided Approach:

Build a Diverse Team - Assemble a multidisciplinary team with expertise in various aspects of the system under analysis, including engineering, maintenance, and risk management.

Identify Failure Causes - Analyze historical data, conduct interviews, and perform site inspections to identify potential failure causes and scenarios.

Understand the System's Inner Workings - Gain a comprehensive understanding of the system's design, operation, and function to accurately assess failure modes and their interactions.

Draw the FTA Diagram - Construct a fault tree diagram using appropriate symbols to represent basic events, intermediate events, and logical relationships between them.

Identify Minimal Cut Sets (MCS), Minimal Path Sets (MPS), or Common Cause Failures (CCF) - Analyze the fault tree to identify the smallest combinations of events that can lead to the top event or failure.

Develop Risk Mitigation Strategies - Based on the analysis, develop proactive strategies to mitigate identified risks, including preventive maintenance, system redesign, or implementation of redundant systems.

Conclusion

What is Fault Tree Analysis? Well, FTA serves as a valuable tool in maintenance management, offering a systematic approach to identifying and analyzing potential failure modes within complex systems. By breaking down system components and analyzing their interactions, FTA enables maintenance teams to proactively identify risks and develop targeted strategies for risk mitigation.

The fault tree diagram provides a visual representation of the relationships between various events and the top event or undesired outcome, facilitating communication and understanding among stakeholders. Through Fault Tree Analysis, organizations can prioritize maintenance efforts, allocate resources effectively, and minimize downtime, leading to improved system operation and safety.

Furthermore, FTA can be integrated with digital solutions such as Computerized Maintenance Management Systems (CMMS) to streamline maintenance processes and harness efficiency gains. By digitizing work processes, organizations can enhance collaboration, reduce errors, and leverage advanced analytical capabilities to improve predictive maintenance practices.

In essence, Fault Tree Analysis empowers maintenance teams to make informed decisions, proactively address maintenance issues, and uphold system reliability and safety standards, ultimately contributing to the overall success of maintenance management initiatives.